Features

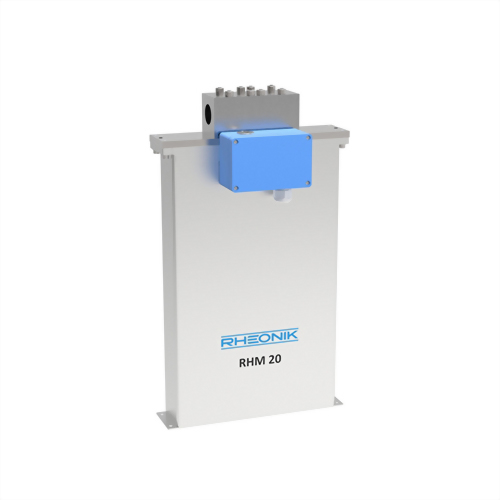

The RHM20 is a 2″ meter designed for general purpose flow measurement without the need for maintanance. Robust and accurate, the RHM20 outperforms other flow technologies at an attractively low cost of ownership.

The specifications contained herein are subject to change without notice and any user of said specifications should verify from the manufacturer that the specifications are currently in effect.Otherwise, the manufacturer assumes no responsibility for the use of specifications which may have been changed and are no longer in effect.

- Standard pressure ratings up to 799 bar (11589 psi)

- Temperature ratings from -196 to 350°C (-320 to 662°F)

- Mass flow uncertainty down to 0.15%

- Density uncertainty down to 0.5%

- Repeatability better than 0.05%

- Nominal measuring ranges between 3 and 300 kg/min

- Accurately measure low flow rates down to 2.25 kg/min

- Unique robust torsion driven oscillation system

- Rheonik AnyPipeFitCommitment brings you the possibility to get any custom process connection type and size for savings on installation costs. Compact design with minimal footprint

- Approved for use in hazardous areas

- Stainless steel case

- Removable connection manifold version available for easy and efficient maintenance

The specifications contained herein are subject to change without notice and any user of said specifications should verify from the manufacturer that the specifications are currently in effect.Otherwise, the manufacturer assumes no responsibility for the use of specifications which may have been changed and are no longer in effect.

Applications

- General Flow Control

- Plant Balance

- Additive Dosing

- Mixing

- Batching

- Package and Container Filling

Specification

Nominal Flow (Qnom)*:

300 kg/min (661.4 lb/min)

Minimum Flow (Qmin)*:

6 kg/min (13.2 lb/min)

Serial Tube/ Single Path:

Flow rates QnomandQminwill be 50% of the above listed parallel/dual tube version

Operating Temperature:

Temperature range options cover applications from -196°C to 350°C (-320°F to 662°F)

Pressure Ratings:

Up to 799 bar / 11589 psi-dependent upon material

Electrical Connection:

Cable entry M25 x 1.5 (standard), M20 x 1.5, ½” NPT, ¾” NPT (optional)

Max. cable length to remote RHE transmitter 100m / 330ft

Sensor Enclosure Materials:

Stainless steel (standard), 316 stainless steel (optional)

Epoxy coated aluminum terminal box (standard), 316 stainless steel terminal box (optional)

Enclosure Type:

Protection class IP65 (standard); IP 66 / NEMA 4X (optional)

Wetted Materials:

1.4571 (316Ti), 2.4602 (Alloy C22), Tantalum, 1.4410 (SuperDuplex)

Seal material (manifold construction): PTFE

Additional/customer specific materials available upon request

Process Connections:

Nearly any -the RHEONIK AnyPipeFitCommitment. Consult factory for types/sizes not listed in thisdata sheet

Pressure Rating Compliance:

Europe –PED: Sound Engineering Practice (SEP),Module A2, Module B3.2+C2

Certifications and Approvals:

ATEX / IECExApprovals for zone 0, 1, 2 (suitably rated RHE transmitter required)

North American Approvals for Class I, Div. 1, Groups ABCD (suitably rated RHE transmitter required)

American Bureau of Shipping (ABS) Product Type Approval for use on marine vessels

Documentation, Testing and Inspection:

All sensors are hydro tested, calibrated and supplied with a traceable calibration certificate. Customized calibration and testing services available

Project Documentation and QA, Services:

Rheonik offers a full set of services for large and complex engineering projects. Typical services offered are, but not limited to:

•Certificates of origin and conformity, mill certificates

•Data books including WPAR, WQS, NDT, test & quality plans, functional testing, calibration procedures, customized packing, factory acceptance etc.

•Start up and commissioning services on/offshore

Options:

Enclosure heating for high temperature applications

Cleaning for oxygen service

Full service painting to project specifications –consult factory

300 kg/min (661.4 lb/min)

Minimum Flow (Qmin)*:

6 kg/min (13.2 lb/min)

Serial Tube/ Single Path:

Flow rates QnomandQminwill be 50% of the above listed parallel/dual tube version

Operating Temperature:

Temperature range options cover applications from -196°C to 350°C (-320°F to 662°F)

Pressure Ratings:

Up to 799 bar / 11589 psi-dependent upon material

Electrical Connection:

Cable entry M25 x 1.5 (standard), M20 x 1.5, ½” NPT, ¾” NPT (optional)

Max. cable length to remote RHE transmitter 100m / 330ft

Sensor Enclosure Materials:

Stainless steel (standard), 316 stainless steel (optional)

Epoxy coated aluminum terminal box (standard), 316 stainless steel terminal box (optional)

Enclosure Type:

Protection class IP65 (standard); IP 66 / NEMA 4X (optional)

Wetted Materials:

1.4571 (316Ti), 2.4602 (Alloy C22), Tantalum, 1.4410 (SuperDuplex)

Seal material (manifold construction): PTFE

Additional/customer specific materials available upon request

Process Connections:

Nearly any -the RHEONIK AnyPipeFitCommitment. Consult factory for types/sizes not listed in thisdata sheet

Pressure Rating Compliance:

Europe –PED: Sound Engineering Practice (SEP),Module A2, Module B3.2+C2

Certifications and Approvals:

ATEX / IECExApprovals for zone 0, 1, 2 (suitably rated RHE transmitter required)

North American Approvals for Class I, Div. 1, Groups ABCD (suitably rated RHE transmitter required)

American Bureau of Shipping (ABS) Product Type Approval for use on marine vessels

Documentation, Testing and Inspection:

All sensors are hydro tested, calibrated and supplied with a traceable calibration certificate. Customized calibration and testing services available

Project Documentation and QA, Services:

Rheonik offers a full set of services for large and complex engineering projects. Typical services offered are, but not limited to:

•Certificates of origin and conformity, mill certificates

•Data books including WPAR, WQS, NDT, test & quality plans, functional testing, calibration procedures, customized packing, factory acceptance etc.

•Start up and commissioning services on/offshore

Options:

Enclosure heating for high temperature applications

Cleaning for oxygen service

Full service painting to project specifications –consult factory

Download

Note : Design and specifications are subject to change without notice.

Note : Please make sure the product and the device which connect with RS-485 are on common ground, avoid damaged product.