Electromagnetic flowmeter ordering precautions

Electromagnetic

flowmeter ordering precautions

Electromagnetic flowmeter are the most common flow measurement instruments in the Industrial, reliable and stable, mainly used to measure cumulative flow and measured bidirectional flow.

To ensure the best performance of the flowmeter in the environment, we suggest the following precautions:

The actual system pressure must be less than the specified pressure of the electromagnetic flowmeter, select the pressure level of the flanges connected on both sides according to the pressure level of the pipe. The lining material needs to consider the corrosiveness of the fluid medium、wearability、and temperature to choose, the characteristics of the medium need to select the electrode material of the electromagnetic flowmeter.

According to the principle of electromagnetic flowmeter, conductivity needs to achieve measurement requirements, the resistivity of pure water is about 10MΩ/cm(Formula: 1 s/cm = 1 Ω-1 /cm), the lower conductivity, the required flow rate lower( less than 3m/s ), Conversely, the conductivity is too high, the measurement accuracy will be lower and general requirements are less than 1 x 10-2 s/cm ( equivalent to be greater than 100Ω/cm )

According to the purpose and function of the measurement select the corresponding accuracy level, the universal electromagnetic flowmeter performance is quite different. The basic error of the gauging instrument with high precision is(±0.5% ~ ±1%)R, The gauging instrument with low precision is(±1.5% ~ ±2.5%)FS. The operating temperature must meet the temperature requirements specified by the flowmeter, according to the requirements of the installation and the environment, choose to use a compact type electromagnetic flowmeter or remote type electromagnetic flowmeter.

eYc

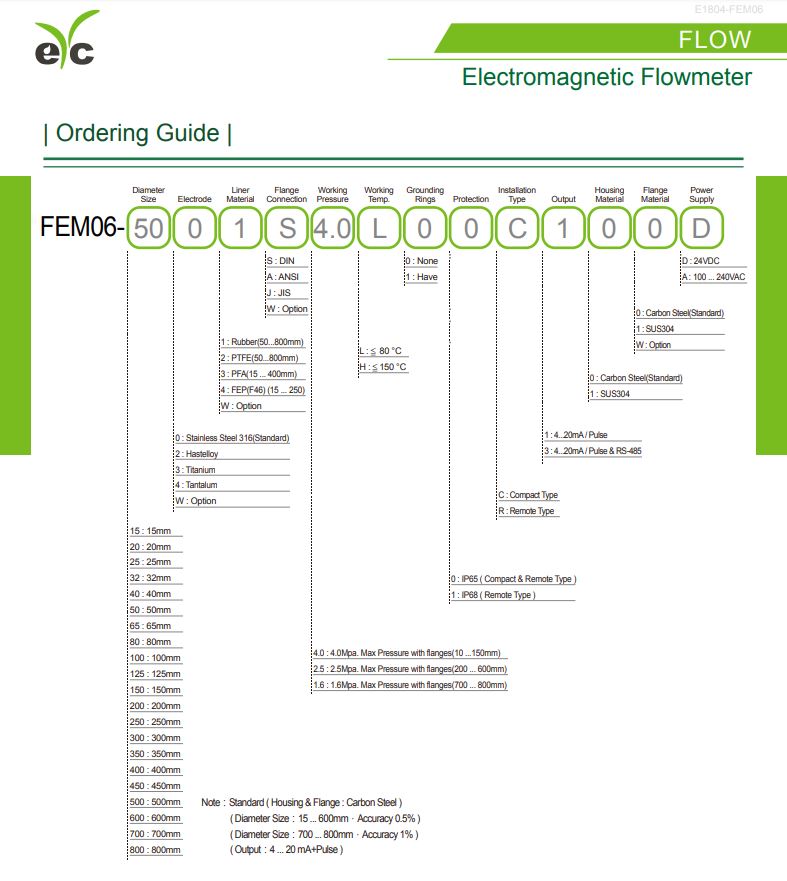

FEM06 Electromagnetic Flowmeter ordering guide as reference, for more

information, please contact eYc salesman.