Exploring Airflow Measurement Technologies in Laminar Flow Cleanroom Environments

Exploring Airflow Measurement Technologies in Laminar Flow Cleanroom Environments

Laminar Flow refers to air moving in a unidirectional, stable, and low-velocity manner. It is critical in surgical settings, aseptic processing, and wafer fabrication. Traditionally, designers rely on regulations to install HEPA filters, FFU units, and ensure sufficient air changes to maintain cleanliness. However, in practice, non-uniform face velocities and obstructions from personnel and equipment often cause turbulence or "dead zones," allowing contaminants to accumulate.

Laminar flow environments serve as the foundation for high-level contamination control and are widely applied in semiconductors, healthcare, and GMP pharmaceutical industries. Traditional cleanroom designs typically depend on pressure differentials, air change rates, and supply air capacity. Yet, under real-world conditions such as uneven face velocities, localized turbulence, and equipment shielding, actual airflow patterns may differ significantly from theoretical expectations.

Currently adopted pressure differential monitoring and estimated airflow rates fail to accurately reflect local airflow anomalies or provide long-term records for audits. Both engineering consultants and end users have reported the need for a highly sensitive, real-time, and BMS-compatible low-velocity airflow monitoring solution.

Comparison of Cleanroom Laminar Flow Types

|

Flow Type |

Applicable Cleanliness Class |

Airflow Description |

Main Advantages |

|

Vertical Laminar Flow |

Class 1~100 |

Air flows vertically downward from ceiling filters, quickly removing contaminants |

Stable airflow, rapid removal of pollutants, suitable for high cleanliness |

|

Horizontal Laminar Flow |

Class 10~1000 |

Air flows horizontally from one side of the cleanroom and is exhausted on the opposite side |

Lower construction cost, suitable for medium to low cleanliness |

|

Turbulent Flow |

Class 1000~10000 |

Air moves in a non-uniform, diffusive pattern |

Simple to construct, highly flexible, ideal for low cleanliness requirements |

Application of FDM06-L Low Air Flow Transmitter (Laminar Type)

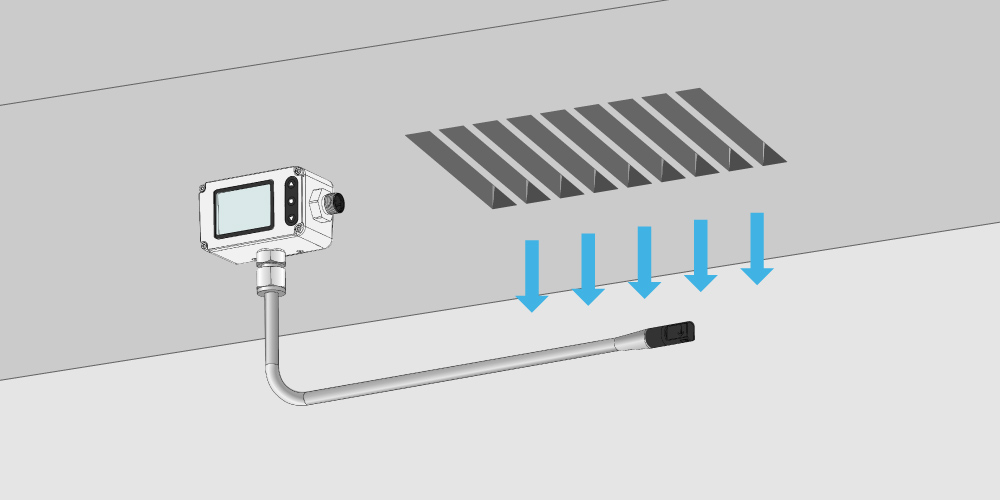

Laminar flow is a high-level airflow control strategy used in cleanroom design, especially in aseptic drug production, biomedical testing, surgical spaces, and micro-contamination-sensitive processes. It is characterized by uniform, stable, low-velocity, and unidirectional airflow—either vertical or horizontal—aimed at swiftly removing particles from the operation zone and avoiding stagnation or turbulence that may compromise cleanliness. In such environments, face velocities are typically maintained within the 0.3 to 0.45 m/s range, requiring sustained, directional, and stable flow fields.

The FDM06-L adopts a bidirectional thermal mass airflow measurement design, specifically engineered for low-speed and slight turbulence conditions. It offers ultra-low starting sensitivity (<0.05 m/s) and accuracy of ±(1% of mv + 0.05 m/s), capable of real-time monitoring at FFU outlets, laminar flow hoods, or central operating workstations. The transmitter enables detection of whether airflow is continuously present, consistently moving, or exhibiting directional deviation, helping verify compliance with ISO 14644’s face velocity uniformity requirements.

To address common user pain points such as undetected insufficient airflow or directional bias causing back-contamination, the FDM06-L provides real-time detection and output signals (Modbus, 4–20 mA, Relay). It can be integrated with FFU controllers or alarm systems. The plug-and-play modular design with on-site LCD display also facilitates airflow tuning and compliance validation directly on-site.

Key Design Features of FDM06-L (Laminar flow Type)

● High Sensitivity: Measurement range ±0.05 ... 2.00 m/s, capable of detecting subtle changes in laminar zones.

● Fast Response: 0.5-second response time.

● Excellent Stability: Built-in automatic temperature compensation and linear correction.

● Modular Outputs: Supports RS485 Modbus, 4–20 mA, Relay outputs, and local display modules.

Application Scenarios

Case 1: Sterile Operating Room

FDM06-L (laminar flow type) is used to monitor whether airflow above the surgical table is continuously present and directionally stable. The face velocity is set between 0.3–0.5 m/s; if it falls below the threshold, an alert is triggered for the HVAC system to adjust accordingly.

Case 2: GMP Sterile Pharmaceutical Process

Installed in key laminar flow hood zones (LAF) for real-time airflow monitoring during aseptic drug compounding or filling operations. Supports data logging and batch reporting.

Case 3: Semiconductor Laminar Production Zone

FDM06-L (laminar flow type) is placed at FFU outlets and laminar workbenches in wafer processing areas for calibration and continuous airflow monitoring. Integrated into systems for cleanroom event recording.

Compliance of FDM06-L (Laminar flow Type) with International Standards

Airflow Monitoring Requirements in Laminar Environments

According to ISO 14644-1, ISO 14644-3, EU GMP Annex 1, and USP <1116>, cleanroom and aseptic process regulations emphasize the following for laminar airflow control:

● Work zones must maintain unidirectional, uniform airflow (UDAF)

● Face velocity should be within the defined range (typically 0.36 ... 0.45 m/s)

● Airflow must have sufficient coverage and continuity to avoid stagnation and turbulence

● Directional consistency and continuous flow must be demonstrable, free from contamination interference

※ Data compiled from international cleanroom and aseptic process guidelines: ISO 14644-1, ISO 14644-3, EU GMP Annex 1, USP <1116>

The FDM06-L (laminar flow type) transmitter is specifically designed to meet the above standards. Its bidirectional thermal mass architecture enables precise monitoring of laminar airflow presence and direction and promptly alerts abnormalities. It provides a reliable, data-driven approach to verifying flow uniformity—effectively addressing blind spots such as velocity decay, local obstructions, or operational disruptions.

Sensor type : Hot-wire sensor

Turndown ratio : 100 : 1

Measuring range : ±(0.00 ... 2 m/s)

Output : 4 ... 20 mA / 0 ... 10 V / Relay / RS-485

Accuracy : 0.05 ... 2.00 m/s:±(1% of mv+0.1 m/s)

IP rating : IP65