Challenges of Micro Airflow Measurement and Reverse Flow Risk in Positive and Negative Pressure Control Environments

Challenges of Micro Airflow Measurement and Reverse Flow Risk in Positive and Negative Pressure Control Environments

In critical spaces such as positive pressure (e.g., clean production areas in pharmaceutical factories) and negative pressure (e.g., isolation wards, bioreactor rooms), maintaining stable and unidirectional airflow is the core protective mechanism to prevent contamination spread and block cross-infection. The industry currently relies on differential pressure transmitters as the primary monitoring method, if air will flow steadily along the pressure gradient, which is then used to control air dampers, access control, or alarm systems. However, this design has a key blind spot: the existence of differential pressure does not guarantee actual airflow, nor can it determine whether the airflow is being directed correctly.

In practice, even if a constant pressure difference is maintained between two zones, the air may briefly stagnate or reverse due to door openings, equipment operation, or external turbulence. Traditional systems are unable to detect these occurrences. These 'invisible risks' are often overlooked but pose a potential threat to contamination prevention in clean processes or epidemic control effectiveness in isolation wards. While differential pressure is a necessary condition, it is not a sufficient one—relying solely on it to determine airflow status no longer meets the safety requirements of today's high-sensitivity applications.

Why Differential Pressure Sensors Cannot Fulfill the Task of Unidirectional Airflow Monitoring?

1. Differential Pressure ≠ Airflow Kinetic Energy

Differential pressure is a static indicator of a pressure gradient and cannot directly indicate whether air is continuously flowing at a stable velocity. In practice, even when the differential pressure value appears normal, airflow may stop or reverse momentarily due to channel blockage, equipment obstruction, or door opening — all of which cannot be detected.

2. Differential Pressure Cannot Identify Airflow Direction

When reverse airflow occurs (e.g. air flows from a contaminated zone into a clean zone), the differential pressure value may remain unchanged, but it cannot signal the incorrect airflow direction. This poses a high-risk warning in negative pressure isolation wards or positive pressure cleanrooms.

3. System Delays and Obstruction Risks

In environments where doors open and close frequently, differential pressure sensors often experience detection delays. They cannot reflect actual changes in the airflow field in real-time, nor can they determine whether the air is stagnant.

Positive Pressure Isolation Applications

|

Application Area |

Purpose |

|

Cleanrooms |

Prevent dust from entering the clean process area |

|

Protective Isolation Room |

Protect immunocompromised patients from external infections |

|

BSL Clean Areas |

Prevent contamination from high-risk zones into cleaner zones |

|

Aseptic Process Area in the Pharmaceutical/Biotech Industry |

Maintain a sterile environment to prevent product contamination |

|

Aseptic Production Area for Food/Beverage |

Prevent microbial and particulate contamination of food |

|

Optical/Optical Component Assembly Area |

Prevent particles from damaging precision components |

|

Server Rooms and Control Rooms |

Protect instrumentation and control equipment from contamination |

Negative

Pressure Isolation Applications

|

Application Area |

Purpose |

|

Negative Pressure Isolation Wards |

Preventing the spread of infection |

|

FOUP/EFEM in Semiconductor and Precision Manufacturing |

Prevent the spread of infections |

|

BSL-3/4 Laboratories |

Biological containment, complete air isolation |

|

Negative Pressure Isolation Chambers |

Isolation of patients during transport and emergency response |

|

Animal Experiment Facilities |

Require stage-wise negative pressure in animal flow zones to prevent cross-contamination |

FDM06-L Bi-directional Low Air Flow Thermal Mass Transmitter (Overflow type) for Positive and Negative Pressure Measurement

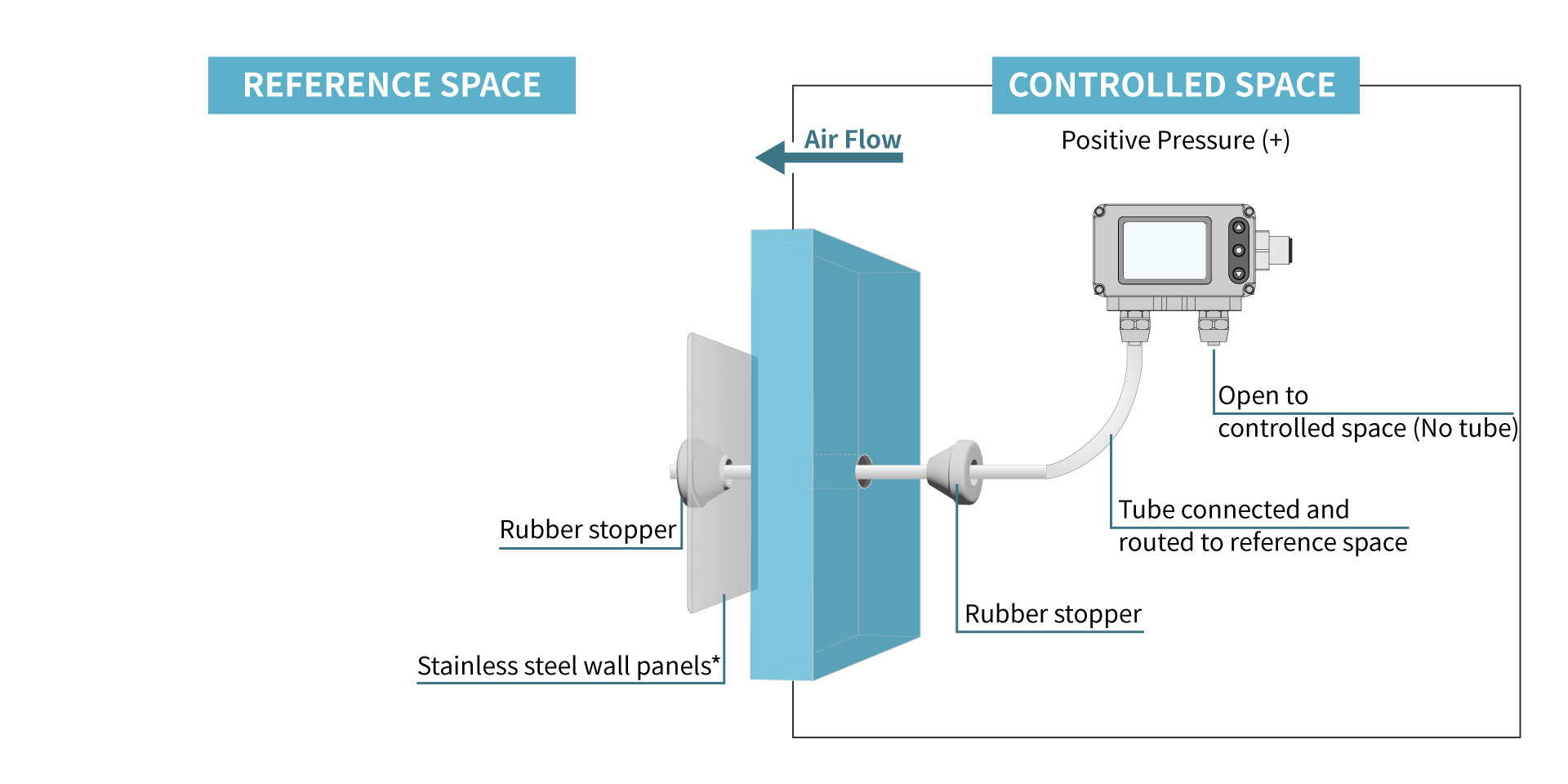

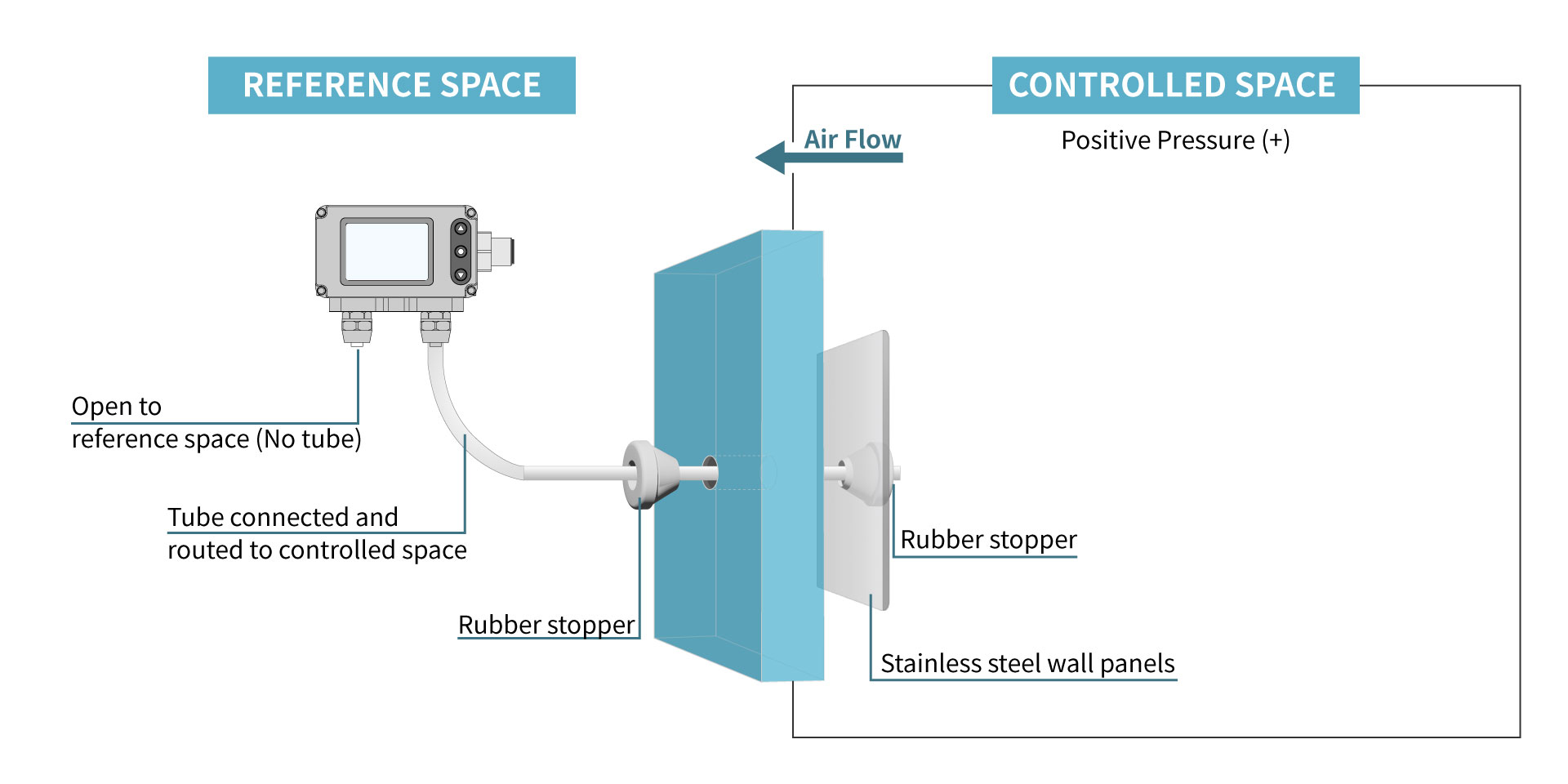

Positive and negative pressure are important measurements in cleanroom design for maintaining airflow direction. They are often installed between two adjacent zones to drive air from high cleanliness areas toward low cleanliness areas using pressure gradients to prevent backflow of suspended particles or contaminants. This airflow is typically lateral, low-speed, and stable unidirectional flow, with air velocity typically between 0.2 to 0.4 m/s, which imposes strict requirements on flow direction consistency and continuity.

This product adopts a thermal mass bidirectional measurement structure, capable of providing high-resolution real-time detection of such low-speed directional airflow. It can identify changes in airflow direction and effectively compensate for blind spots in differential pressure detection under conditions of momentary reverse flow or airflow interruption. Its ± (1% of mv + 0.05 m/s) accuracy and stable response characteristics make it suitable for installation at clean zone exits, airlock midpoints, or buffer channel nodes to ensure airflow remains from the clean zone to the outside, avoiding backflow risks.

FDM06-L Bi-directional Low Air Flow Thermal Mass Transmitter (Overflow type) Design Features

● Bidirectional airflow measurement: Capable of detecting airflow direction and identifying reversals in real-time, especially critical for positive/negative pressure control environments.

● Ultra-low airflow design: Measures air velocity as low as 0 ... 2 m/s, capable of detecting extremely low flows.

● Easy system integration: Supports digital/analog output, unit conversion, flow calculation, and customizable relay alarm settings.

● Convenient setup: Configurable directly via the device or through UI software for ease of use.

● Simple installation design: Can be mounted on wall openings, with the sensing probe minimally invasive to the airflow path, achieving stable signal measurement with basic guiding accessories.

Application Scenario Analysis

Case 1: Airflow Direction Monitoring in Negative Pressure Isolation Wards

In medical facilities, negative pressure isolation rooms are designed to prevent pathogen leakage. A critical requirement is to ensure that air only exists the ward and does not flow back. Originally relying only on differential pressure sensors to maintain negative pressure, frequent door openings often lead to airflow reversal into the corridor.

FDM06-L (Overflow type) can be used to measure this. By detecting bidirectional airflow in real-time, reverse flow can be identified now of door opening, triggering enhanced exhaust and audio-visual alarms to achieve active airflow control.

Case 2: Airflow Measurement at Clean Corridor Junctions

In semiconductor factories, clean corridors connect zones of varying cleanliness levels. It is necessary to maintain airflow from higher to lower cleanliness zones to avoid particle return and contamination. However, installing only differential pressure sensors makes it difficult to ensure actual airflow exists and is stable.

FDM06-L (Overflow type) can be installed at corridor junctions to set a low airflow alarm threshold and direction detection. It allows real-time monitoring of 'whether airflow exists' and 'whether direction is correct'. If airflow disappears or reverses, the system can link to access control or adjust airflow controllers to improve controllability.

Compliance and Empirical Validation of FDM06-L (Overflow type) with International Standards

1. International Requirements for Airflow Direction Monitoring

According to the CDC Guidelines for Environmental Infection Control in Health-Care Facilities, ASHRAE 170, ISO 14644, and EU GMP Annex 1, the design of negative pressure isolation rooms, pharmaceutical cleanrooms, and clean corridors must meet the following requirements:

● Air should flow from clean zones to contaminated zones (unidirectional airflow)

● A sufficient pressure differential must be maintained between zones

● Air flow direction and velocity changes should be monitored when necessary

● In the event of airflow interruption or reversal, immediate warning and control intervention are required

This product is equipped with real-time bidirectional airflow detection capabilities that fulfill the above regulatory requirements. It can serve as supplementary verification for differential pressure systems, especially by providing actual airflow behavior data during door opening events or system anomalies.

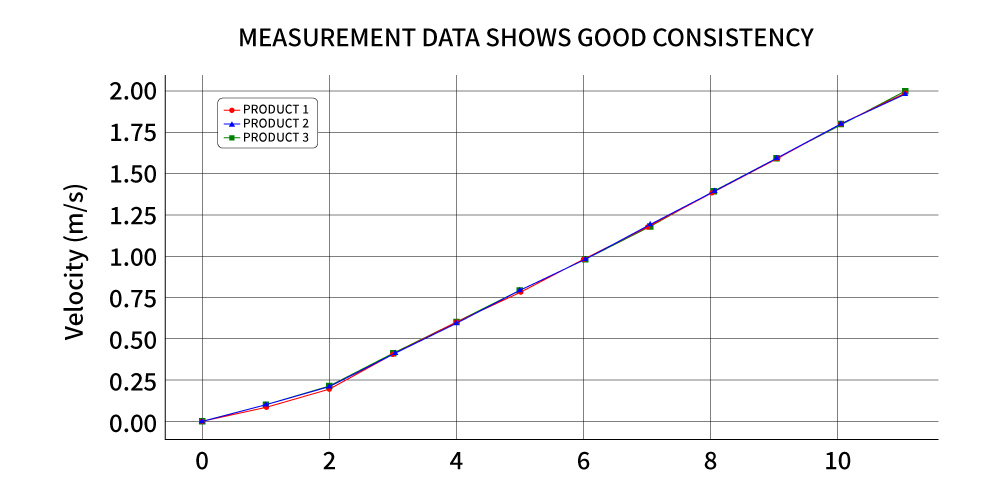

2. Real-Flow Wind Tunnel Calibration Using Laboratory-Grade Equipment

To ensure the measurement accuracy and stability of the FDM06-L Bi-directional Low Air Flow Thermal Mass Transmitter (Overflow type) in ultra-low flow environments, laboratory-grade equipment was used during the R&D and testing phases for real-flow wind tunnel calibration.

The laboratory is equipped with airflow testing tunnels that comply with ISO 17025 standards and integrates sonic nozzle calibration mechanisms along with low-turbulence flow channel designs. These features provide high reproducibility and traceability.

During the calibration process, real-flow comparisons across the 0.05 to 2.0 m/s velocity range were conducted at multiple points. Combined with high-precision reference instruments, point-by-point compensation and nonlinear corrections were applied to establish a complete full-range response curve. This calibration strategy significantly enhances the sensor's resolution and dynamic response performance, making it especially suitable for cleanrooms, pharmaceutical applications, semiconductors, laminar flow workstations, and airflow isolation measurement scenarios.

Through this wind tunnel standardization process, the product is factory-calibrated to deliver accurate, stable, and repeatable airflow measurements—providing a robust technical foundation for demanding environments.

The FDM06-L Bi-directional Low Air Flow Thermal Mass Transmitter (Overflow type) provides what is most lacking in clean zone positive and negative pressure monitoring: verifiable evidence of actual airflow presence and direction.

Only by confirming “whether airflow exists” and “whether it is flowing in the correct direction” can cleanroom airflow control be considered qualified and trustworthy.

Sensor type : Hot-wire sensor

Turndown ratio:100:1Turndown ratio : 100 : 1

Measuring range:±2 m/s

Output:4 ... 20 mA / 0 ... 10 V / Relay / RS-485

Accuracy:±1%

IP rating:IP65