eyc-tech Revealing Differential Pressure Measurement Technology

eyc-tech Revealing Differential Pressure Measurement Technology

Introduction |

Differential pressure measurement technology plays a crucial role in the industrial sector, being used to monitor and control the operation of various fluid systems. By measuring the pressure difference, fluid flow can be determined, enabling system monitoring and process control. This article will delve into the principles, techniques, and applications of differential pressure measurement technology.

Definition of Differential Pressure |

Differential pressure measurement is based on calculating the pressure difference between two points in a fluid to infer flow velocity and volume. The formula is ΔP = P1 − P2, where P1 and P2 are the pressures at the two points, with ΔP representing dynamic pressure. Commonly used in environments such as cleanrooms and hospitals, where positive pressure prevents external contaminants from entering cleanrooms, and negative pressure wards prevent internal contaminants from escaping, to prevent cross-contamination of viruses and bacteria. Through thin-film, piezoelectric, and hot-wire differential measurement technologies, system operation safety and efficiency are ensured.

Differential Pressure Measurement Principles |

Piezoresistive and hot-wire are common differential measurement principles, each utilizing different physical effects to measure pressure differences, ensuring system safety and efficiency.

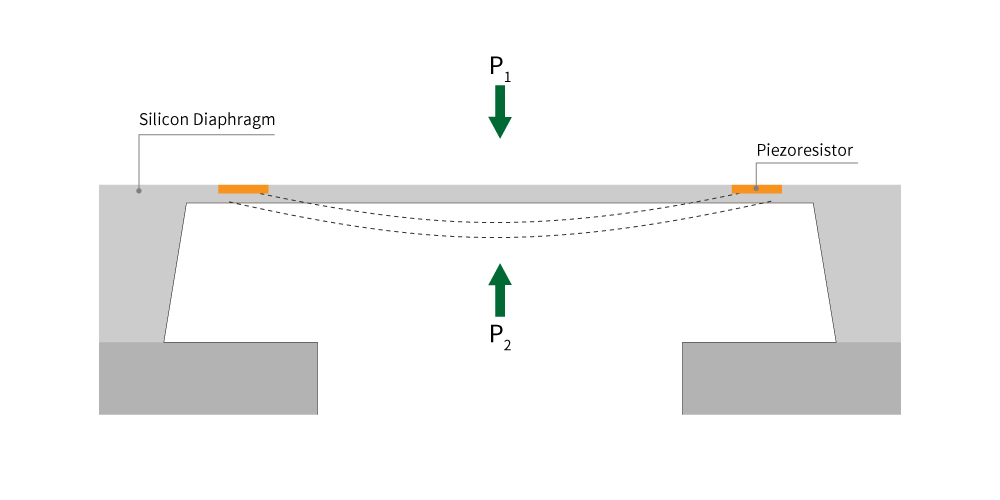

- Piezoresistive Differential Pressure Measurement: The working principle of a piezoresistive differential pressure transmitter is based on the piezoresistive effect, a phenomenon where the electrical resistance of a material changes when subjected to stress. The main structure of the sensing element includes a diaphragm made of silicon material and piezoresistive elements integrated on the diaphragm. When there is a pressure difference on the two sides of the sensing element, the diaphragm deforms due to the pressure difference. This deformation causes the piezoresistive elements to change their shape, resulting in a change in their electrical resistance. The amount of resistance change is proportional to the pressure difference between the two sides, and after signal processing, an electrical signal proportional to the pressure difference is obtained.

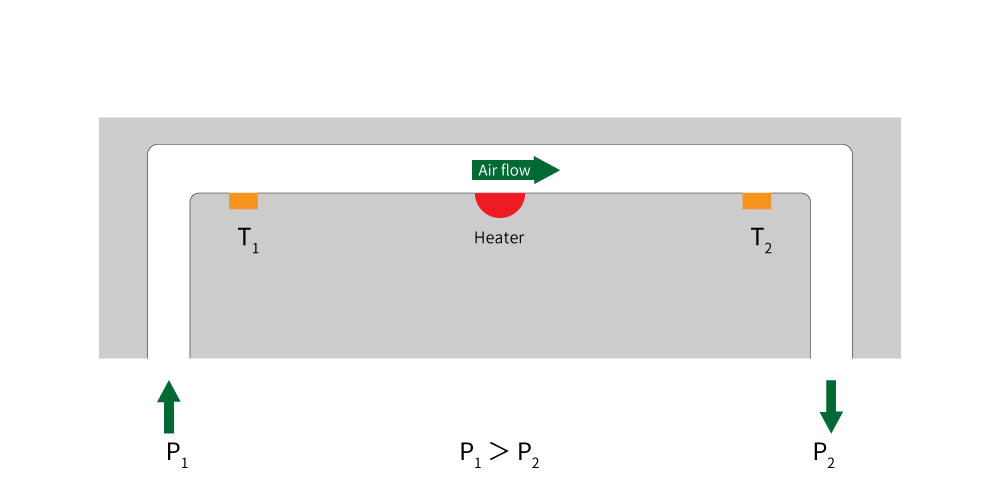

- Hot-Wire Type Differential Pressure Measurement: Hot-wire type differential pressure measurement technology calculates the pressure difference by measuring the air flow rate. When there is a pressure difference between two measurement points, air flows from the high-pressure side to the low-pressure side through a channel inside the transmitter. The channel contains a heating element and two temperature sensors. By comparing the heating and temperature changes, the air flow rate can be precisely measured, which in turn allows the calculation of the pressure difference. This technology can detect extremely low air flow rates, making it possible to precisely measure small pressure differences. Additionally, hot-wire type measurement technology has the characteristic of low zero-point drift, meaning the transmitter can maintain a stable initial zero point even after prolonged use, ensuring measurement precision and reliability.

Differential Pressure Combined with Pitot Tubes / Venturi Tubes: Precision Air Velocity Measurement |

-

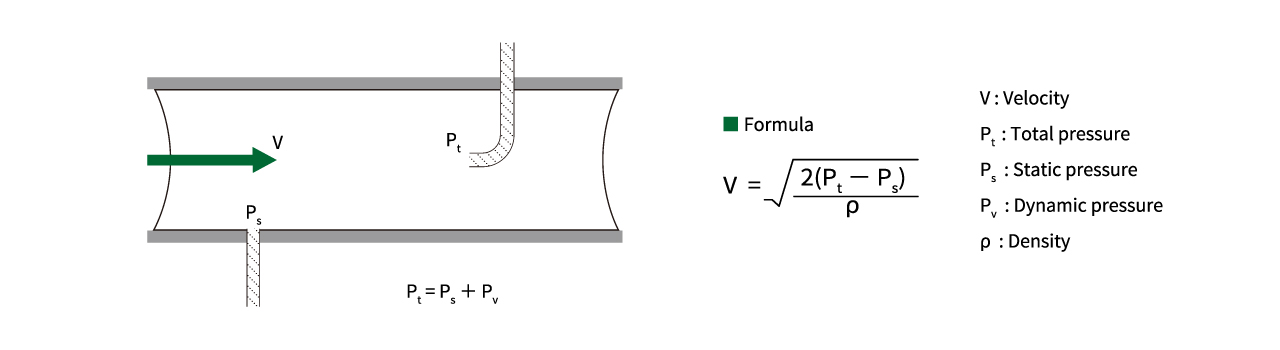

Pitot Tube: Pitot tube is a basic device used to measure fluid velocity. By measuring dynamic and static pressures, it can calculate flow velocity. An average pitot tube is an advanced device with multiple pressure holes on the probe, distributed across the cross-section of the fluid pipeline, to average the pressures from these holes to obtain a more premise average flow velocity. In terms of gas cleanliness, differential air velocity indicators are less sensitive to dust. However, dust may still block the holes of the Pitot tube after a long period of use, so it is still recommended to be installed behind the filter and regularly cleaned to reduce the impact of particles on the Pitot tube.

-

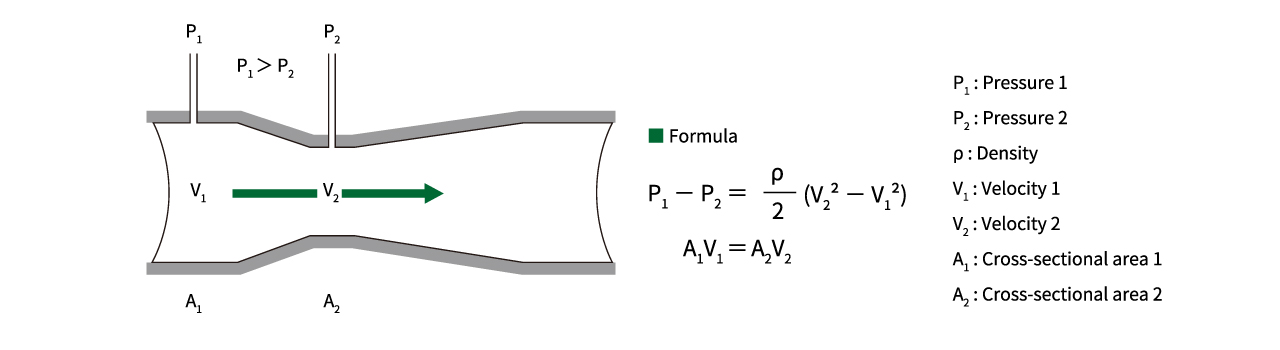

Venturi Tube: The Venturi tube is a flow measurement device designed based on the Venturi effect and is often used in conjunction with differential pressure transmitters. When flow passes through the narrow center of the Venturi tube, its velocity increases while the pressure decreases; this phenomenon is known as the Venturi effect. According to Bernoulli's principle and the continuity equation, the pressure difference between the inlet section and the center is proportional to the square of the fluid velocity, and the product of the velocity and the cross-sectional area at different points remains constant. Therefore, by measuring the differential pressure, the velocity at the center can be calculated. The Venturi tube has significant advantages in flow measurement, including high accuracy and low pressure loss, allowing for precise measurement while minimizing energy loss. It is suitable for various fluids, including gases, liquids, and steam. Its robust structure, with no moving parts, requires minimal maintenance, reducing operational costs.

Applications |

- HVAC: Differential pressure transmitters can be used for filter monitoring to check the clogging status of filters. They are also applied in duct pressure monitoring, measuring the airflow in air conditioning systems, and detecting leaks. These applications help improve the operational efficiency of HVAC systems and provide a comfortable indoor environment.

- Cleanrooms and Hospitals: One of the most common applications of differential pressure measurement is in cleanrooms and hospitals. By maintaining positive pressure, cleanrooms prevent external contaminants from entering, ensuring cleanliness. Conversely, negative pressure wards prevent internal contaminants from escaping, thus preventing cross-contamination of viruses and bacteria.

- Industrial Process Monitoring: In industrial process monitoring, differential pressure measurement is widely used in various scenarios, including pipeline flow measurement, gas pressure monitoring, and liquid level control.

|

|

Conclusion |

Differential pressure measurement technology plays an indispensable role in applications such as cleanrooms and air compressors, providing critical technical support for system monitoring and process control. Through the combination of Pitot tubes or Venturi tubes with differential pressure transmitters, we can achieve precise measurement of fluid flow rates and efficient control, thereby improving production efficiency, reducing costs, and ensuring the safe operation of measurement processes.