Ultrasonic Flow Monitoring Dual Solutions for Water & Wastewater Management

Ultrasonic Flow Monitoring Dual Solutions for Water & Wastewater Management

In modern industrial operations, the precision of fluid monitoring has become a decisive factor for energy efficiency, process stability, and regulatory compliance. Whether it is wastewater discharge management, data-center liquid cooling reliability, or cooling tower energy optimization, the ability to obtain reliable data without interrupting operation is a challenge for both engineering design and on-site management.

At the same time, with ESG and carbon-neutral requirements becoming increasingly stringent, flow data is no longer just for process monitoring—it is the foundation for carbon-emission calculations.

Relationship Between Ultrasonic Flowmeters and Carbon Emission Calculation

1. Flow Data = Basis of Energy Consumption

● Ultrasonic flowmeters accurately monitor water usage, circulating cooling-water flow, and wastewater discharge.

● These data can be converted into pump operation time × power × electricity consumption.

● Electricity consumption is then multiplied by the local grid CO₂ emission factor (kg CO₂/kWh) to calculate carbon emissions.

Example: A cooling tower circulating 500 m³ of water per hour, with pumps consuming 10 kW, can calculate daily emissions by multiplying power use with the grid’s emission factor.

2. Wastewater Discharge and Regulatory Compliance

● In wastewater treatment, flow data directly determines daily discharge volumes.

● When authorities require reporting of daily discharge and carbon footprint, ultrasonic flowmeters provide accurate evidence.

● Particularly for ESG reports or ISO 14064 carbon inventories, wastewater energy consumption must be linked to carbon emissions.

3. Cooling Water and Liquid-Cooling System Efficiency

● In data-center liquid cooling or cooling towers, flow data not only affects cooling performance but also calculates energy consumption per unit flow.

● Insufficient flow reduces cooling efficiency, leading to energy waste and higher carbon emissions.

● Flow monitoring supports PUE (Power Usage Effectiveness) and carbon efficiency metrics.

Ultrasonic flowmeters ≠ direct CO₂ measurement, but they provide the essential baseline data for carbon calculations.

Industry Applications & Installation:

|

|

|

|

|

|

|

|

|

|

|

|

FUM06 Ultrasonic Flowmeter (Professional Type)

● Covers tap water, cooling water, chemical solutions; DN50–DN300 pipe ranges.

● 0.1 m/s ultra-low velocity detection for data-center liquid cooling and low-flow wastewater.

● 100:1 turndown ratio, high sensitivity for both large and small flow changes.

● Multiple outputs (4–20 mA / 0–10 V / RS-485 Modbus) for seamless integration with SCADA, BMS, or DCS.

● Optional temperature probe for energy and thermal-efficiency analysis.

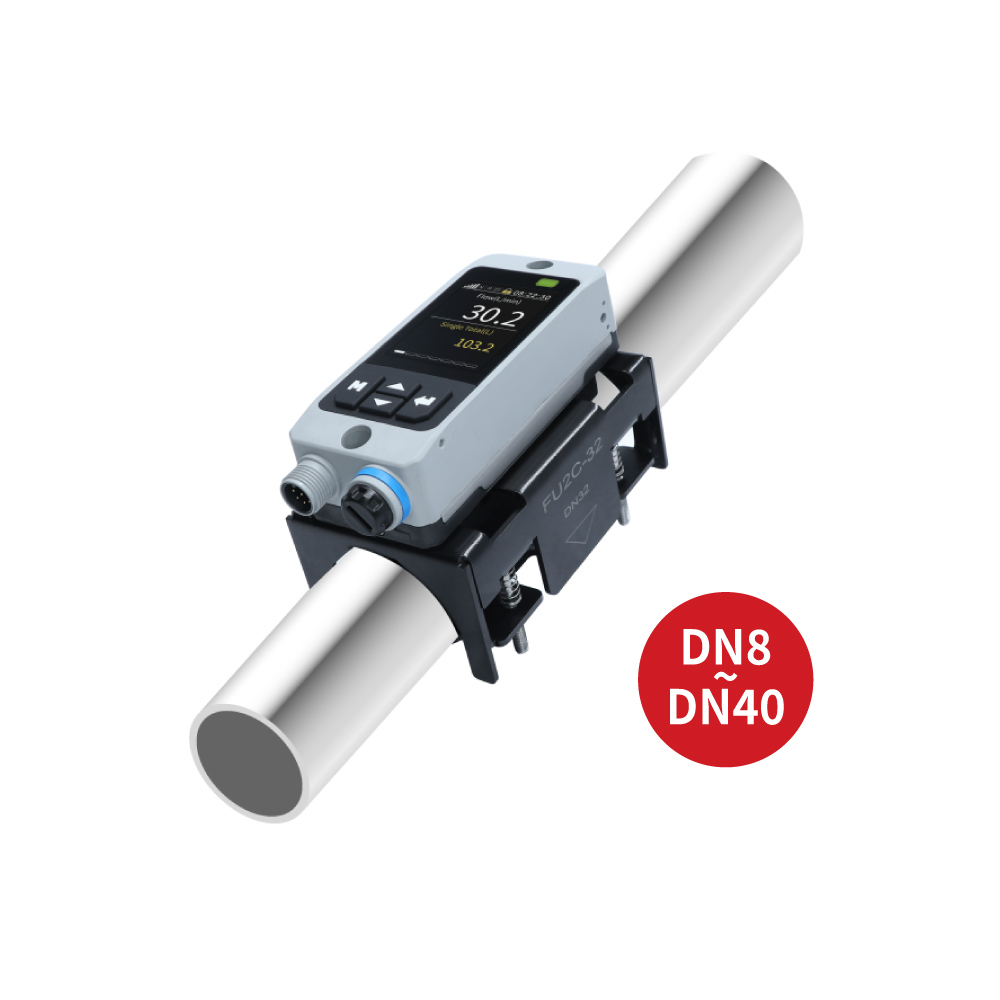

FUM03 Clamp-on ultrasonic flowmeter (Quick Type)

● Suitable for water, circulating cooling water, and some chemical liquids; DN8–DN40 small pipe diameters.

● No shutdown, no pipe cutting—fast installation, ideal for cooling towers, circulation lines, and wastewater monitoring.

● 2-inch TFT display with intuitive operation, showing real-time flow and totals.

● Multiple outputs (NPN/PNP, analog, RS-485, relay, pulse) for easy field integration.

● Cost-effective solution for rapid industrial deployment.

With FUM06 and FUM03 combined, enterprises achieve both high-precision monitoring and quick-install practicality:

● Ensure regulatory compliance with wastewater treatment.

● Guarantee server, cooling stability and energy optimization in data centers.

● Improve energy efficiency and reduce O&M costs in cooling towers.

No shutdown, no pipe cutting, simple installation, the best solution for smart manufacturing and sustainable development.