Coolant Flow Velocity Measurement Solutions for AI Server Liquid Cooling Systems

Coolant Flow Velocity Measurement Solutions for AI Server Liquid Cooling Systems

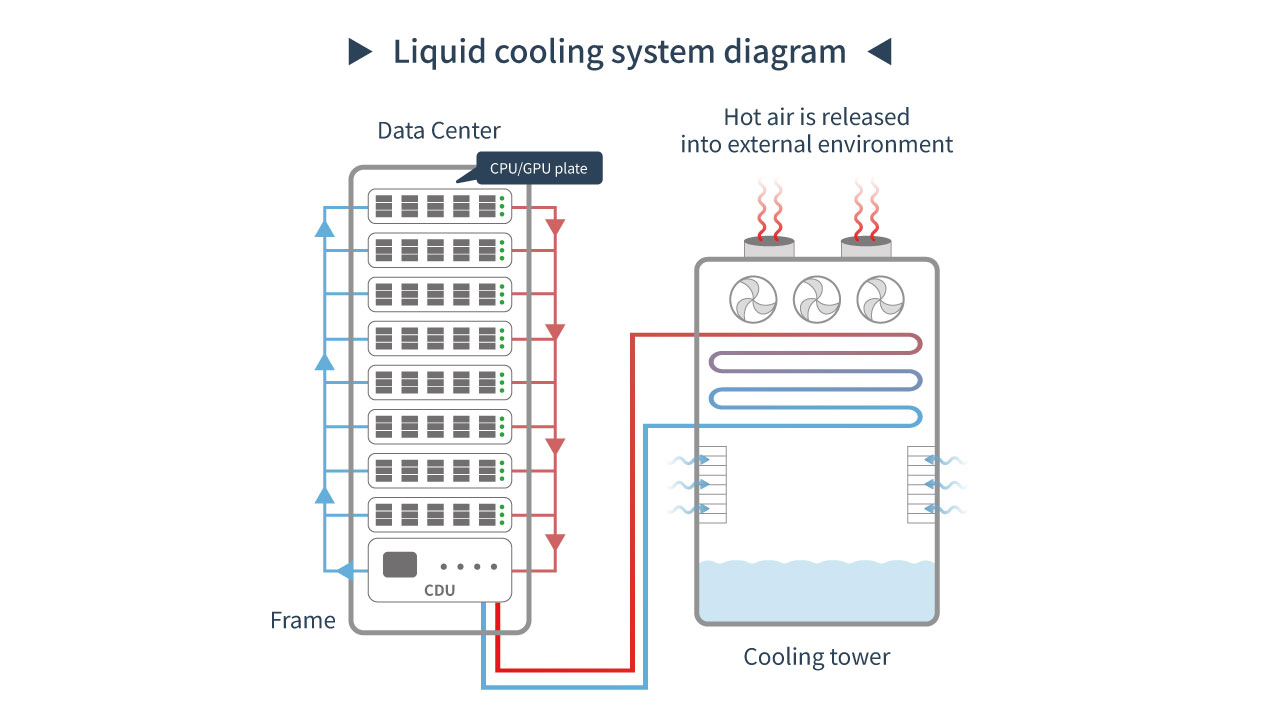

As the power consumption of AI servers and high-performance computing continues to increase, liquid cooling has become a key thermal solution for high-heat-density equipment. The stability of a liquid cooling system depends not only on coolant temperature, but also equally on whether the coolant can circulate smoothly and consistently within the loop.

Therefore, during system operation, coolant flow velocity and circulation performance become critical indicators for determining normal operating conditions. For AI server liquid cooling applications, eyc-tech provides flow velocity transmitters suitable for liquid cooling systems, helping users establish clear, actionable, and long-term measurement architectures.

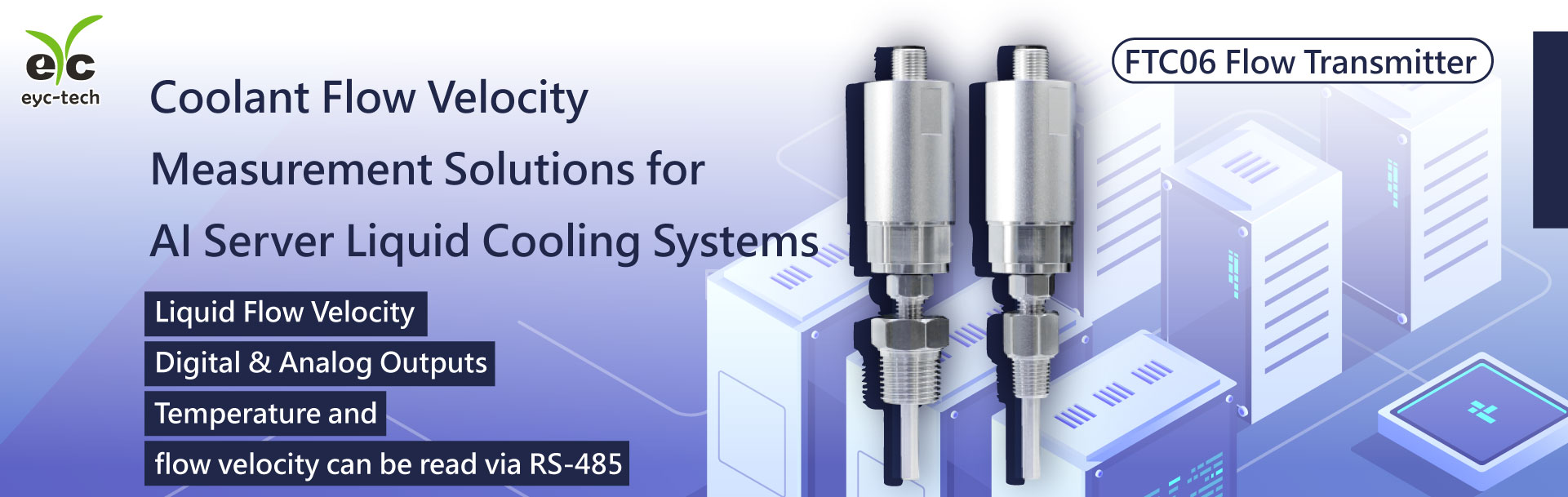

FTC06 Flow Transmitter

A flow velocity measurement product designed for industrial and equipment applications, suitable for measuring coolant flow velocity in liquid cooling systems. It can be deployed at key pipeline sections within the liquid cooling loop as an important measurement point for determining whether coolant circulation is stable.

Measurement and Application Features

● Suitable for liquid cooling systems and liquid circulation loops

Can be installed in liquid cooling pipelines to measure coolant flow velocity and monitor circulation status.● Supports digital and analog outputs

Allows flexible integration into existing monitoring or control systems as an information source.

● RS-485 parameter configuration and data transmission

Enables centralized management, measurement configuration, and system integration.

Rack-Based Liquid Cooling Architecture — Measuring and Evaluating Coolant Flow Conditions

In liquid cooling or direct liquid cooling (DLC) architectures, cooling components and coolant loops are typically installed inside servers or racks. Their circulation status directly affects cooling efficiency and overall system stability. Through flow velocity measurement, the coolant flow condition within the loop can be reflected in real time, enabling early detection of reduced flow velocity or abnormal circulation.

Recommended Measurement Configuration for Liquid Cooling Systems

FTC06 Flow Transmitter

Installed in rack-level fluid loops or key pipeline sections to measure liquid flow velocity. Temperature and flow data can be obtained via RS-485, serving as an important reference for determining whether liquid cooling system circulation is operating normally and for understanding coolant flow conditions within the loop.

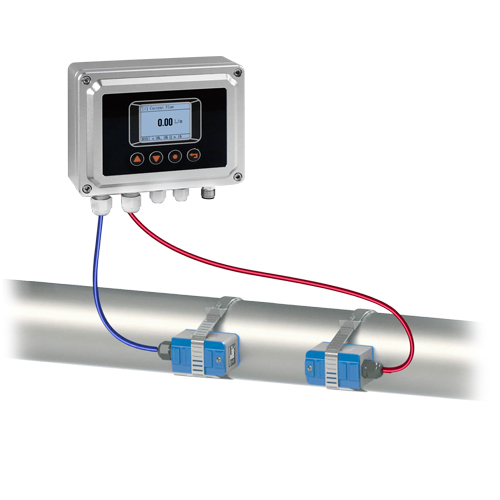

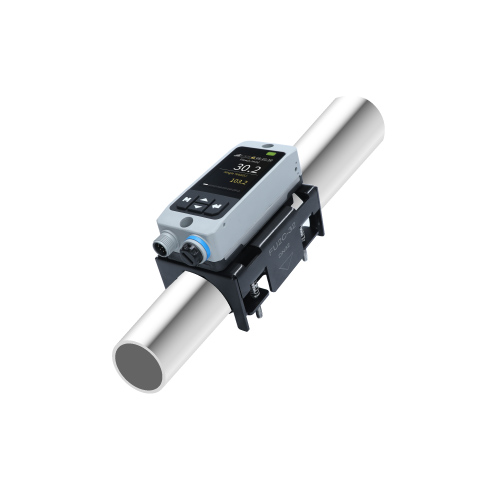

FUM06 Ultrasonic Flowmeter / FUM03 Clamp-on Ultrasonic Flow Meter

Suitable for liquid cooling systems where pipe cutting is not feasible or for existing pipelines. These devices measure pipeline flow using non-intrusive methods as a means of monitoring overall loop operation. FUM06 is suitable for pipe diameters from DN50 to DN300. FUM03 is suitable for smaller pipe diameters from DN8 to DN50. They can be flexibly selected based on actual pipeline conditions, balancing cooling performance and energy management requirements.

P063 Differential Pressure Transmitter

Can be installed upstream and downstream of key components in liquid pipelines—such as cold plates, heat exchangers, or filter elements—to measure differential pressure changes.

By observing differential pressure trends, abnormal system resistance can be identified early, helping detect issues such as flow path obstruction, air bubble accumulation, or reduced cooling efficiency. This measurement approach provides real-time and early-warning monitoring for liquid cooling systems, making overall operating conditions easier to assess.

Features : Rugged aluminum housing, RS-485 temperature and water flow measurement, data logging, for liquid cooling systems.

Sensor type : Pt 50 / Pt 1000

Measuring range : 0 ... 3 m/s

Output : 4 ... 20 mA / RS-485 / NPN

Accuracy : ±2%

IP rating : IP65

Features : Non-intrusive and high-precision measurement, suitable for various fluids and pipe sizes.

Sensor type : Ultrasonic time difference

Turndown ratio : 100 : 1

Measuring range : 0.1 ... 10 m/s

Output : 4 ... 20 mA / 0 ... 10 V / RS-485

Accuracy : ±1% F.S.

IP rating : IP65

Features : Suitable for water, circulating cooling water, and some chemical liquids; DN8~D50 small pipe diameters.

Detection Principle : Transmission Time Difference

Maximum Flow Rate : 19.6 ... 589 L/min

Output : Switch / Analog / RS-485

Accuracy : ±1% F.S.

IP rating : IP65

Features : Stainless full-sealed housing, compact size.

Sensor type : Piezoresistive Diaphragm

Measuring range : 0 ... 16 bar

Output : 4 ... 20 mA

Accuracy : ±0.5% F.S.

IP rating : IP65

Multiple Output for Flexible Liquid Cooling System Integration

FTC06 supports digital, analog, and NPN outputs, allowing flexible integration into existing liquid cooling monitoring, control, or management systems. It is well suited for long-term, high-load operation requirements of AI server racks.

Establishing an Actionable Liquid Cooling Flow Velocity Measurement Architecture

Based on the operational requirements of liquid cooling systems, eyc-tech provides transmitters that can be seamlessly integrated into existing architectures. Continuous monitoring of coolant flow velocity and loop circulation status supports effective analysis and management of system operating conditions.