eyc-tech Apply Transmitter in Industrial Exhaust Air Treatment and Manage Carbon Emission

eyc-tech Apply Transmitter in Industrial Exhaust Air Treatment and Manage Carbon Emission

CONTENTS:

☛ 1. Introduction

☛ 2. Overview of Exhaust Air Treatment Principals

☛ 3. Challenges in Exhaust Air Treatment

☛ 4. Precise Measurement of Air Velocity and Airflow to Mitigate the Global Warming Crisis

☛ 5. eyc-tech Transmitter Solutions for Air Velocity and Airflow

☛ 6. Conclusion

☛ 7. Reference

1. Introduction |

Importance of Exhaust Air Treatment

In industrial processes, such as chemical, petrochemical, electronics, optoelectronics, semiconductors, metal processing, and wastewater treatment, the emission of volatile organic compounds (VOCs) and other exhaust air poses a serious environmental issue. These exhaust air not only pollute the environment but also pose a threat to human health, especially with long-term exposure to high concentrations of harmful exhaust air. Effective exhaust air treatment technologies and monitoring measures are crucial for protecting the environment and public health.

Environmental and Health Impacts of Exhaust Air

VOCs and other exhaust pollutants can lead to deteriorating air quality, potentially causing various health issues, including respiratory diseases, allergic reactions, and other chronic conditions. Additionally, these pollutants can harm ecosystems, affecting the habitats of plants and animals. Therefore, effective treatment and control of exhaust air are key to protecting the environment and health, thereby effectively reducing carbon emissions.

2. Overview of Exhaust Air Treatment Principals |

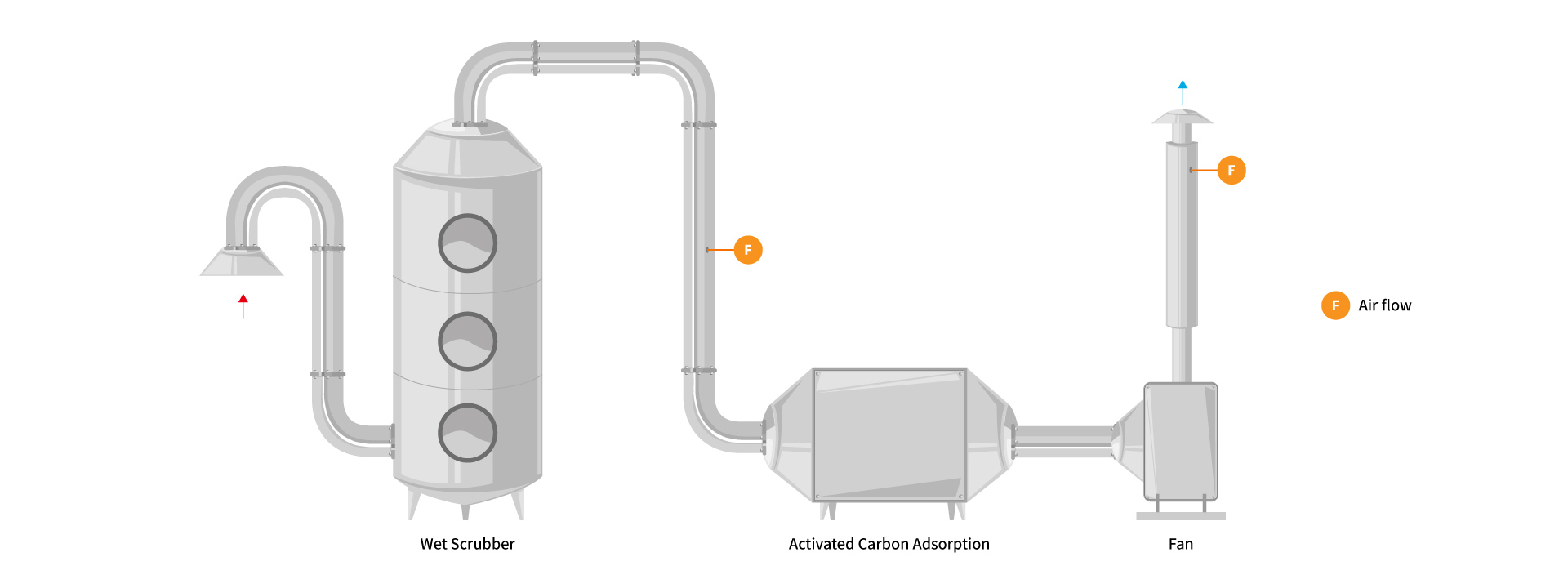

Principle of Exhaust Air Scrubbers

An exhaust air scrubber utilizes the contact between air and liquid to transfer pollutants from the air into the liquid, then separates the clean air from the contaminated liquid to achieve the purpose of air purification. Average air velocity measurement tubes or Pitot tubes, combined with differential pressure transmitters, are used for flow monitoring.

Components of the Exhaust Air Scrubbing System:

The exhaust air scrubbing and collection system consists of a air hood, ductwork, exhaust air treatment equipment, and a chimney. The air hood captures pollutants, the ductwork transports airflow, the exhaust gas treatment equipment ensures compliance with regulatory standards, and the chimney ensures the diffusion of emissions.

Principle of Activated Carbon Adsorption

Taking an activated carbon adsorption tower as an example, the principle of activated carbon adsorption is used to introduce organic air-containing exhaust into the activated carbon filter layer for adsorption, deodorization, and odor removal, thereby achieving air purification. This method is widely applied in the treatment of exhaust air from electronic component production, battery production, pickling operations, laboratory exhaust, metallurgy, chemical, pharmaceutical, painting, food, brewing, and other industries, with the most extensive use in paint spray exhaust air treatment.

Process of Activated Carbon Adsorption Tower: The activated carbon adsorption tower is a dry-type exhaust air treatment device. The process begins with the exhaust air passing through a pre-filter to remove dust and impurities from the air. The air is then cooled to below 40°C by a cooling system. Power equipment sends the air into the adsorption tank for adsorption, where activated carbon adsorbs the polluted air. Finally, the clean air is discharged into the atmosphere through the chimney.

To monitor air pollutants in the exhaust pipeline, the following regulations must be met: For volatile organic compounds, the exhaust air at the purification equipment's intake and emission outlets should be equipped with continuous automatic monitoring facilities, such as airflow transmitters. Therefore, in the activated carbon adsorption tower equipment, transmitters can be installed at each chimney outlet and in the ductwork before filtration. The eyc-tech DPM04 Flow Totalizer can be connected via RS-485 to simultaneously monitor instantaneous and cumulative flow rates.

Exhaust gas treatment flow chart:

3. Challenges in Exhaust Air Treatment |

|

|

|

|

|

|

4. Precise Measurement of Air Velocity and Airflow to Mitigate the Global Warming Crisis |

Taiwan actively promotes carbon footprint and carbon neutrality to address global climate change challenges, aiming to reduce greenhouse air emissions and achieve sus tainable development. According to the "Taiwan's Pathway to Net-Zero Emissions in 2050," the Taiwanese government has implemented various measures to achieve net zero emissions. In exhaust air treatment processes, transmitter applications not only enable real-time monitoring of air velocity and flow but also assist enterprises in carbon footprint management and carbon neutrality practices. Key benefits of eyc-tech transmitter applications include:

- Precise Monitoring: Transmitters provide precise real-time data on exhaust emissions, ensuring compliance with environmental standards. This supports precise data for carbon footprint management and effective carbon emission control, aiding Taiwan's 2050 net zero emission goal.

- Efficiency Improvement: Transmitters help optimize exhaust air treatment processes, reducing energy consumption and costs. Real-time data monitoring allows prompt detection and resolution of anomalies, preventing excessive emissions due to equipment failure or operational errors, supporting Taiwan's efficient energy transition.

- ESG Goal Compliance: Transmitter applications assist enterprises in achieving ESG goals, particularly in environmental protection. Real-time data monitoring and analysis ensure the effectiveness of environmental measures, enhancing the enterprise's environmental image and market competitiveness, and supporting Taiwan's performance in global green initiatives.

- Support for Carbon Neutrality: Transmitters provide essential data for carbon neutrality practices. Enterprises can use transmitter data to develop and adjust carbon reduction strategies, ensuring carbon neutrality targets are met. Additionally, transmitter applications help track carbon emission reductions and assess the effectiveness of reduction measures, providing practical data support for Taiwan's 2050 net zero emission plan.

Through these applications, transmitters play a crucial role in achieving Taiwan's carbon footprint and carbon neutrality vision, promoting Taiwan's leadership in addressing global climate change challenges.

5. eyc-tech Transmitter Solutions for Air Velocity and Airflow |

eyc-tech Exhaust Air diagram:

1. eyc-tech FTM94/95 Industrial Grade High Accuracy Thermal Mass Flow Transmitter

When considering exhaust air emissions, it's essential to take into account the flue air flow rate, flue airflow, flue air temperature, and pressure. Additionally, the characteristics of the exhaust air need to be considered, such as emission type, treatment airflow, density, corrosiveness, moisture content, odor, toxicity, and viscosity. Therefore, when selecting air velocity and airflow transmitters, it is crucial to consider their resistance to high temperatures, corrosion, and dust.

After evaluation, the eyc-tech FTM94/95 Industrial Grade High Accuracy Thermal Mass Flow Transmitter has been introduced, suitable for harsh industrial environments. It features high precision, special dual PT probes, and resistance to high temperatures, pressure, and dust. It can be used for measuring mildly corrosive air, with a range up to 120 Nm/s. The units can be converted between Nm/s (velocity) and Nm³/h (flow rate). The probe is temperature-resistant up to 120°C, with an LCD module for dual-row display. The device has an aluminum alloy housing with IP65 protection for the main body and IP67 for the probe.

The FTM94/95 is a constant thermal mass flow transmitter that uses King's law thermal balance equation to obtain the characteristic curve of the constant temperature thermal mass transmitter. A specially developed multi-stage sample regression method is used to linearize this characteristic curve, making the measured data more precise and stable during signal conversion.2. AFMT Average Flow Measuring Tube (Pitot tube) with Differential Pressure Transmitters for Measuring Air Velocity and Airflow

The eyc-tech AFMT Average Flow Measuring Tube measuring tube can be paired with the PHM330 differential pressure transmitter or the PMM330 indoor differential pressure transmitter to measure air velocity and airflow. The PHM330 differential pressure transmitter, with its aluminum alloy casing, is less affected by external environments, ensuring reliable and stable flow rate measurements. Depending on the user's environmental requirements, the PMM330 indoor differential pressure transmitter can be selected.

The AFMT Average Flow Measuring Tube (Pitot tube) measures the pressure difference between the total pressure and the static pressure of the fluid, then calculates the flow rate. The difference between total pressure and static pressure is the dynamic pressure, which is the pressure caused by fluid flow. Dynamic pressure is proportional to the square of the air velocity, so by measuring dynamic pressure, the fluid velocity can be calculated.

3. Transmitters Paired with DPM04 Flow Totalizer

The DPM04 Flow Totalizer can be paired with FTM94/95, PHM330 or PMM330. In addition to displaying the instantaneous measurements, it can calculate the cumulative amount over time. The DPM04 can receive common output signals and features RS-485 communication, relay control, and signal retransmission functions. When improving the measurement of exhaust air treatment, it can effectively provide data references and assist in process control.

6. Conclusion |

Effective exhaust air treatment is crucial for protecting the environment and public health, and it is a necessary condition for the sustainable development of enterprises. Our high-precision air velocity and airflow transmitter can help companies achieve precise monitoring and optimization of exhaust air treatment processes, improve treatment efficiency, reduce energy consumption, comply with environmental regulations, and enhance corporate ESG performance.

With increasingly stringent environmental regulations and continuous technological advancements, exhaust air treatment technology will continue to evolve. Our company will keep innovating to provide more efficient and environmentally friendly solutions, aiding the world in achieving its 2050 net-zero emission goal.

7. Reference |

- Taiwan Executive Yuan Environmental Protection Agency, fugitive emission control, air pollution prevention specialist training materials

- Taiwan's Pathway to Net-Zero Emissions in 2050

![eyc-tech [即將上市] eyc-tech AFMP 平均風速測管](/uploadfiles/423/Products/Picture/eyc-tech-afmp-00.jpg)