Precision Monitoring: Optimizing HVAC for Smart Energy Savings

Precision Monitoring: Optimizing HVAC for Smart Energy Savings

CONTENTS:

☛ Introduction☛ Commercial Buildings Management

☛ AHU(Air Handling Units)

☛ Cooling Systems

☛ Parking Lot Management

Introduction |

HVAC (Heating, Ventilation, and Air Conditioning) refers to systems responsible for regulating indoor air temperature, humidity, and ventilation flow, as well as controlling the separation of indoor and outdoor air to ensure a comfortable and healthy indoor environment. Within HVAC systems, heating provides consistent thermal energy, ventilation ensures the circulation and freshness of indoor air, and air conditioning controls indoor temperature and humidity to create a suitable indoor environment.In recent years, with the increasing awareness of energy conservation and environmental protection, the HVAC field has continuously optimized high-efficiency measurement equipment to improve system performance, reduce energy consumption and costs, and minimize environmental impact.

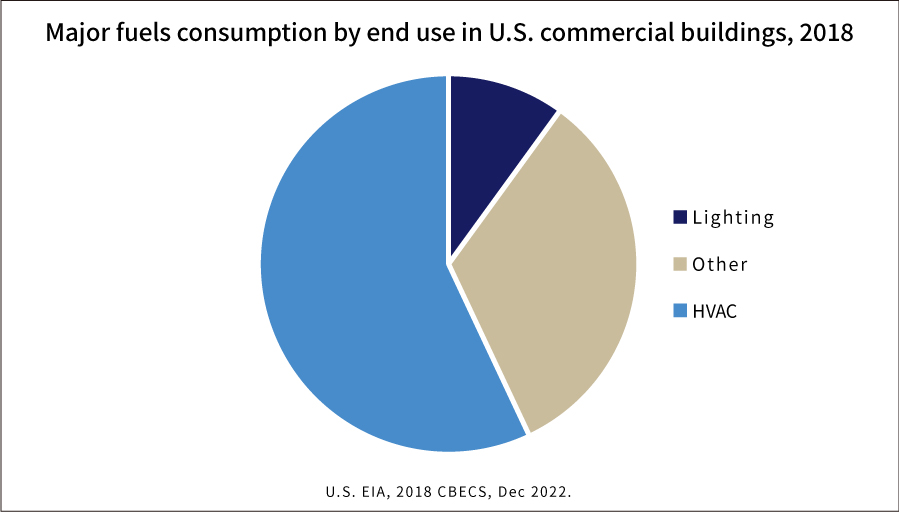

According to the Industrial Assessment Centers (IACs) database, the average energy saving potential of SMEs is 8.03%, of which HVAC accounts for about 50% of office building energy consumption, including ventilation, water supply, and drainage, and Parking lot management, etc., are also used to control indoor temperature and humidity to maintain appropriate air quality, and improve the comfort of the office environment. Therefore, doing a good HVAC design is indeed the best way for SMEs to reduce operating costs.HVAC systems are widely used across various fields, with some of the primary application scenarios including office buildings, cooling water systems, clean rooms, and parking garages:

Commercial Buildings Management |

Early commercial buildings used the building automation system BAS (Building Automation System), but each system lacked a shared management interface, and some equipment could not be controlled to achieve intelligence and automation; or basic operations such as pressure and temperature transmitter and switches were used as basic Control, so it is difficult to effectively manage energy facilities and control budgets. On the overall system, electricity accounts for two-thirds of the total energy consumption, of which lighting, office equipment, and HVAC account for 90%.

In order to effectively control energy, office buildings have gradually used Building Energy Management System (BEMS) to do Energy control is to integrate HVAC with other systems to control a number of equipment in the building, such as pumps, fans, valves, dampers, and compressors. By consolidating and linking previously separate functional systems for energy control, it allows for the regulation of temperature, humidity, and airflow in different areas of the building. A well-designed BEMS, combined with the use of high-precision, long-term stable, and durable transmitters for monitoring and control, can save 5% to 20% of energy costs annually.

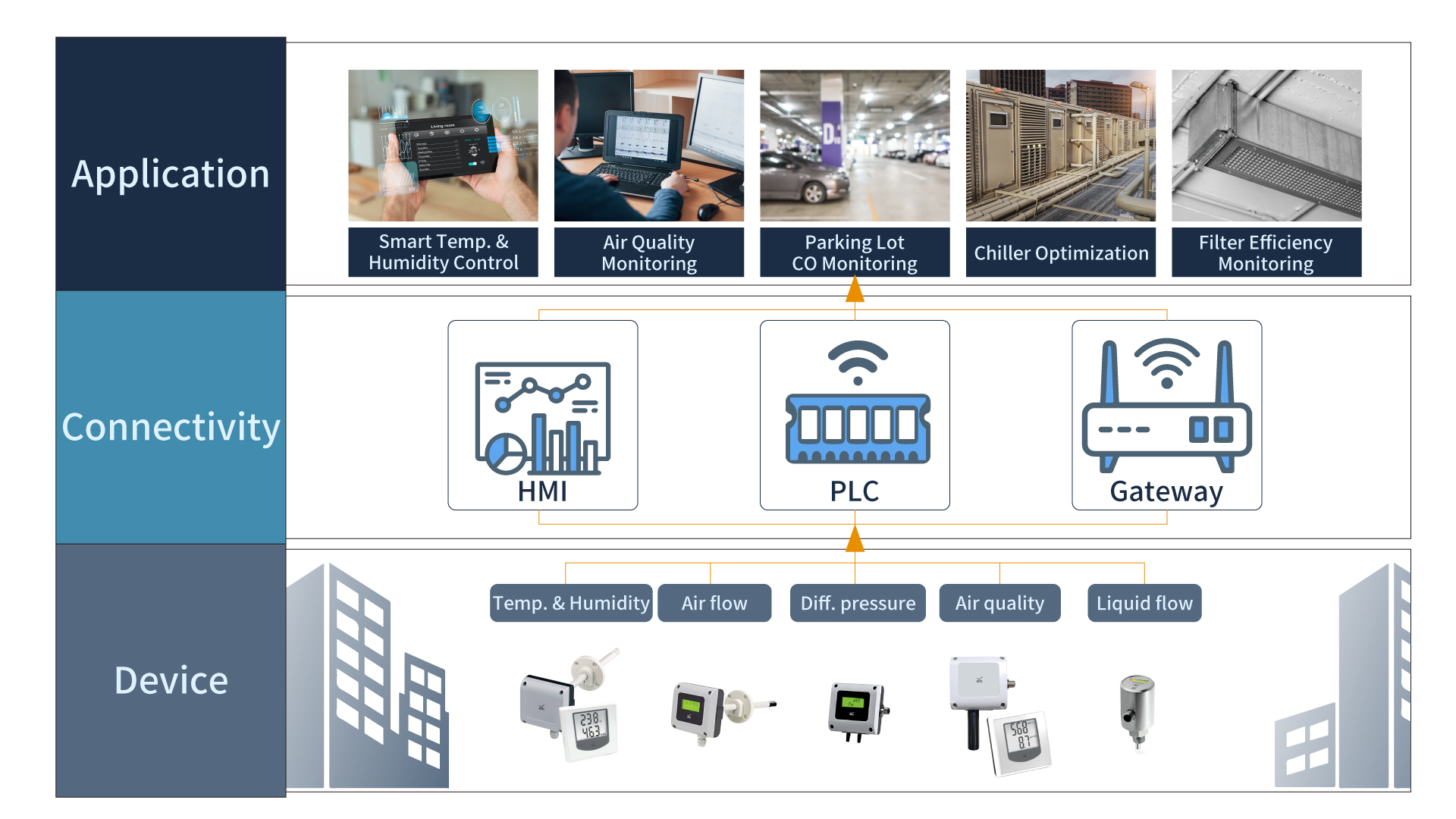

HVAC mainly controls and properly adjusts the temperature, humidity, air circulation and air cleanliness in the building. The transmitter installed in the HVAC system measures the indoor environment mainly to obtain more detailed parameters for the operation of the equipment. Such as temperature, humidity, CO2, PPM, pressure, air velocity, air flow, etc., the measured values are transmitted to the data collector to the central control room through digital or analog signals, and the room is controlled by computer monitoring. Environmental control of grasping the equipment operation status and also can collect data and analyze the environment in combination with the cloud system, so as to effectively control the indoor environment.

Air quality is a major factor affecting environmental comfort. The temperature and humidity of the environment not only influence our perceived comfort but also directly impact our work and rest states. Elevated levels of carbon dioxide can lead to dizziness, fatigue, and lack of concentration, thus affecting productivity and health. PM2.5 fine particulate matter is not only harmful to the respiratory system but can also trigger various respiratory diseases. eyc-tech's Air Quality transmitters can precisely measure temperature, humidity, carbon dioxide, and PM2.5 in real-time, providing stable and reliable data. With flexible connectivity options and dedicated planning software, they offer comprehensive solutions for the environment, improving energy efficiency and ensuring indoor air quality meets standards.The air distribution system is the part of the HVAC system that is closest to the user. A good air distribution system can make the user feel comfortable and save energy. However, the air distribution system often encounters these problems:

1. Uneven indoor temperature

2. Difficulty in adjusting the airflow

These issues lead to increased energy waste and inefficient use of resources.

At this time, it will be equipped with temperature and humidity transmitter, flow-switches, real-time monitoring instruments, etc. Integrated control and limit demand or load/unload control. Adjusting temperature or ventilation control according to demand can effectively solve excessive energy loss, etc. Achieve effective energy-saving and control the optimization of startup and shutdown.

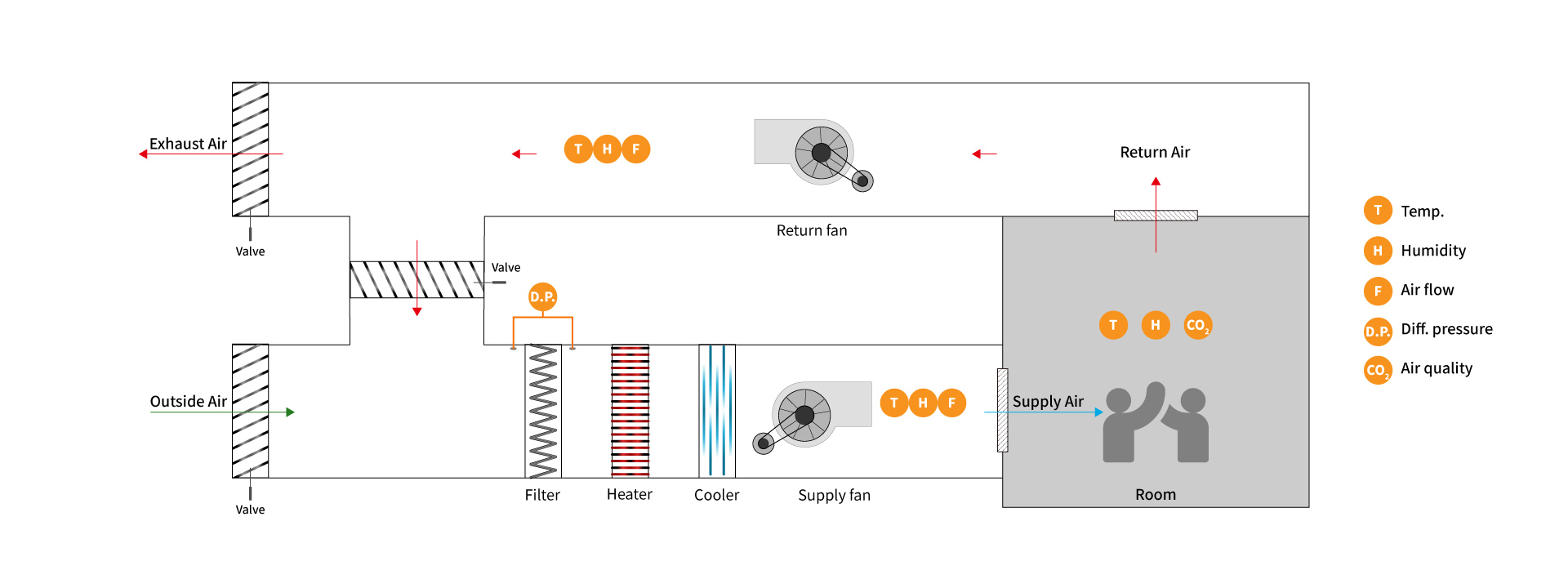

Schematic diagram of transmitter in office building HVAC:

AHU(Air Handling Units) |

In the air handling unit (AHU) system, transmitters play a critical role in ensuring the system's operational efficiency and maintaining the stability of the indoor environment. Here are several transmitter applications within the AHU:

- Temperature and Humidity Transmitter are installed at the return air vent, in front of the supply fan, and within the indoor space. These transmitters monitor the humidity of the supply air in real-time, and by adjusting the heating or cooling systems, they ensure that the indoor air temperature remains within the desired range, achieving both energy efficiency and comfort.

- Air Flow and Air Velocity Transmitter are installed at the supply air outlet and in front of the return fan to monitor the fan's airspeed and volume. These transmitters help maintain proper airflow circulation and ventilation within the AHU, optimizing indoor air circulation and improving air quality.

- Differential Pressure Transmitters are mainly installed at the filter. They monitor the pressure difference across the filter. As dust and debris accumulate in the filter, the pressure difference increases. By referring to the measured data, you can determine whether the filter needs to be cleaned or replaced, ensuring air quality is not compromised and the system continues to run efficiently.

- CO₂ Transmitter are installed in indoor spaces to monitor the concentration of carbon dioxide in real-time. When the amount CO₂ become too high, you can make the system introduce more fresh air to maintain air quality, ensuring comfort and health in the indoor environment.

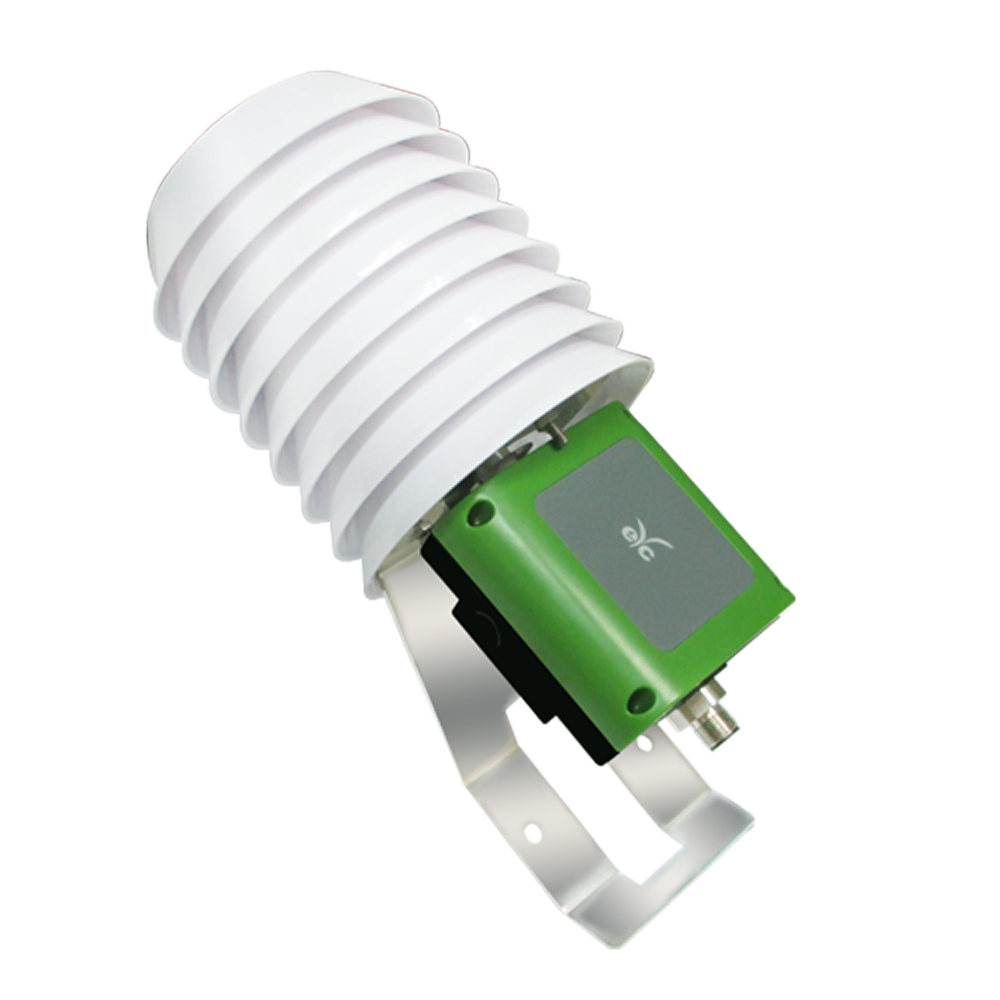

THS30X Series Multifunction

Temp. & Humid. Transmitter

FTS34/35

Air Velocity Transmitter

PMD330

Differential Pressure Transmitter (Indoor)

THG03

CO2 Temperature & Humidity Transmitter

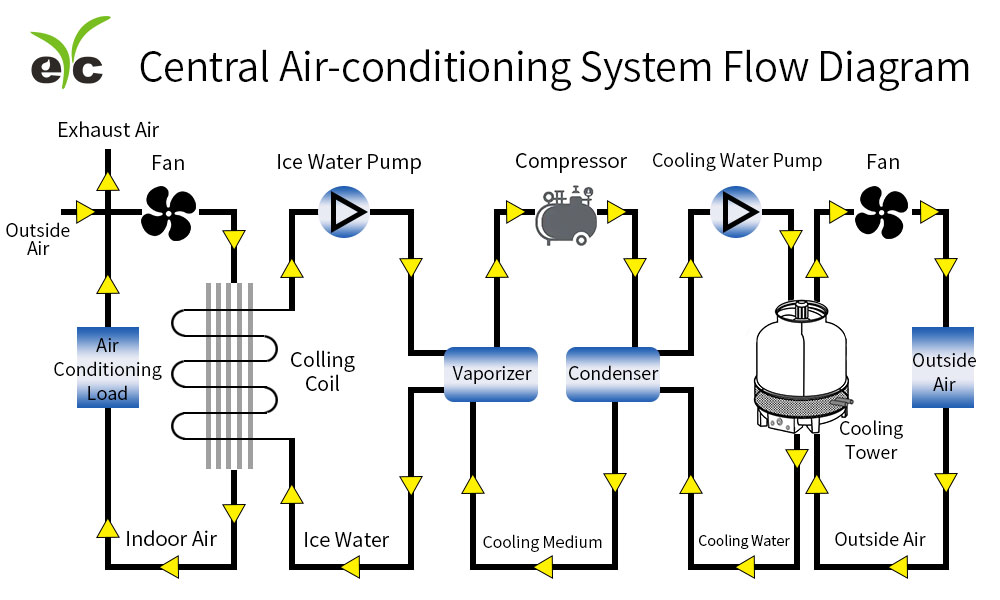

Cooling Systems |

Industrial manufacturing, technology industries, and data centers often require efficient cooling systems to maintain the stability of equipment and systems. In cooling systems, the core components commonly include cooling towers and chillers, which are selected based on the cooling needs of the specific application process. Cooling towers are typically used to cool water by removing heat from the system through the evaporation of water, thereby lowering its temperature. On the other hand, chillers utilize compressors to cool refrigerants.

Water-cooled chillers measurement items are as follows:1. Temperature measurement of main unit water supply and return water

2. Power consumption and main unit load of the main unit during operation

3. Main unit water level measurement

The following formula can be used to calculate the freezing capacity that can be produced when the air conditioner is running:

Q = m x Cp x ΔT

Q: Change in enthalpy (ΔH), m: Mass, Cp: Specific heat, ΔT: Change in temperature (Final Temperature – Initial Temperature = ΔT)

Used for air conditioning, the measurement transmitter will make the control system for temperature, humidity, air cleanliness, and air circulation, adjust the cooling energy output of the air conditioner, and will directly affect the user feeling (such as people, things, important machinery, and equipment) .

Water Measuring range: 1-200 cm/s

Sensor type : Resistance Temperature Detector (RTD)

Proof pressure:10 bar

Operating Temp.: -20-+60°C

Operating Humid. 0 ... 100%RH

Parking Lot Management |

|

Parking lot management is an indispensable part of urban life. Detecting changes in carbon monoxide concentration in parking lots is crucial for maintaining the health and safety of users. Managers can promptly identify safety risks and take appropriate measures, such as enhancing ventilation or temporarily restricting user access. Continuous monitoring of carbon monoxide levels can significantly improve the safety of parking lots, providing users with a more comfortable and secure parking environment. |

Its advantages include many physical quantities in terms of functions, economical, high accuracy, long-term stability, low power consumption, durable, and optional ISO/IEC 17025 (TAF/ILAC) calibration report.

Contact Us > > en.en.yuden.com | T E L : + 8 8 6 - 2 - 8 2 2 1 - 2 9 5 8 | e - m a i l : info@yuden.com.tw

F