Precise Environmental Monitoring in Cleanrooms; eyc-tech Transmitter

Precise Environmental Monitoring in Cleanrooms; eyc-tech Transmitter

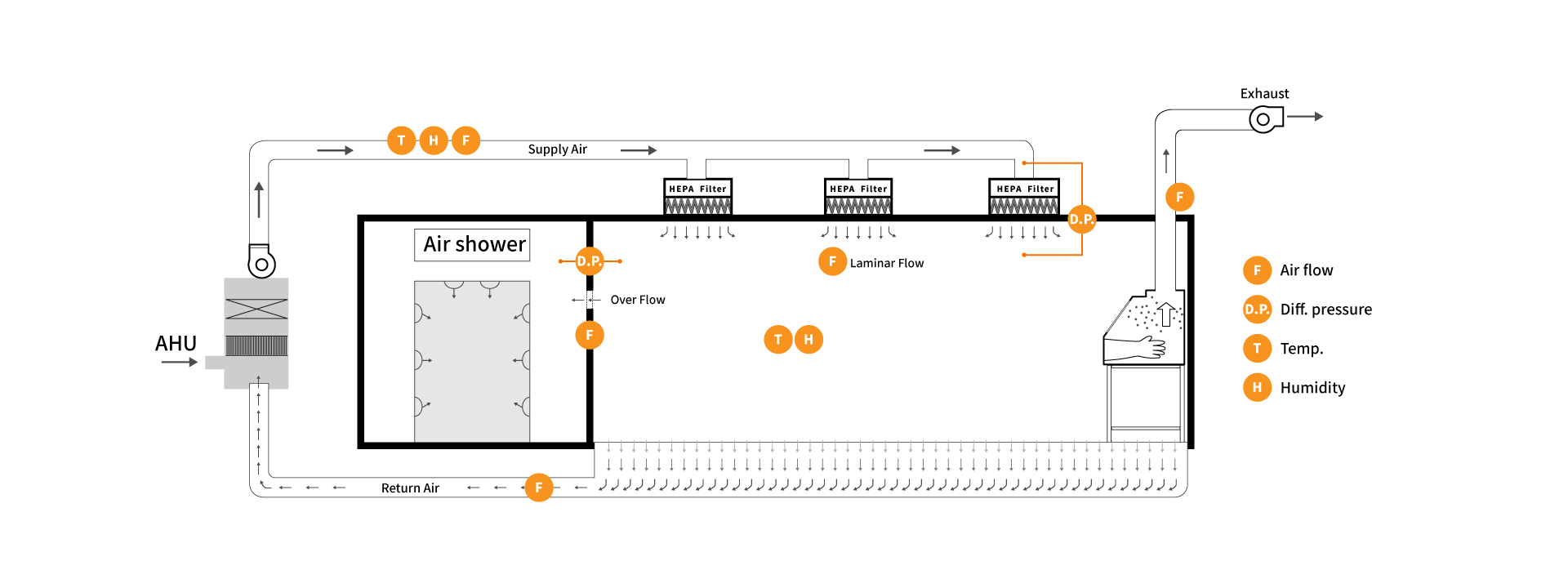

A cleanroom is an environment designed to control the levels of microscopic particles and microorganisms in the air. These rooms are common in places requiring high levels of cleanliness, such as pharmaceutical, semiconductor manufacturing factories, and biological laboratories. To ensure that the environment within a cleanroom remains uncontaminated, strict control of the air pressure differential between the interior and exterior is necessary.

A differential pressure transmitter is a key device used to monitor the air pressure differential between the inside and outside of a cleanroom. It can continuously monitor changes in the pressure differential to ensure that the internal air pressure is always higher than the external pressure, thereby preventing external contaminants from entering the cleanroom.

Additionally, the ventilation system of a cleanroom is a crucial component for maintaining clean indoor air. These ventilation systems typically include filters, air velocity transmitters, and other control devices to ensure proper airflow and cleanliness levels.

Thermal mass flow transmitter are used to monitor the velocity of the airflow, ensuring that the ventilation system provides sufficient air velocity to effectively draw microscopic particles in the air to the filters, thereby achieving air purification. If the air velocity is insufficient, particles may remain suspended in the air and not be effectively filtered out, compromising the cleanliness of the indoor environment.

With the assistance of transmitters, the cleanliness of a cleanroom can be effectively maintained, ensuring the purity of the manufacturing process, thereby improving product quality and production efficiency.

Functions of Transmitters in Cleanroom:

Monitors the pressure difference between the interior and exterior of the cleanroom to maintain stable environmental pressure. By keeping the pressure difference within a safe range, the system prevents external contaminants from entering the cleanroom, ensuring the purity of the manufacturing process.

Accurate monitoring of temperature and humidity changes in cleanrooms and ventilation ducts ensures the stable control of processes. These data help prevent adverse effects of temperature and humidity fluctuations on product manufacturing, maintaining consistent product quality.

Monitors the speed of air movement to ensure that the airflow within the cleanroom meets specified standards. This helps evenly distribute clean air, preventing the accumulation of pollutants or particles in any area.

eyc-tech possesses a variety of transmitters designed for precise measurement and monitoring of cleanroom environments, aiding in the maintenance of cleanliness and ensuring a reliable manufacturing environment. It serves as an indispensable tool for measuring cleanroom environments accurately.