Optimize Aeration Tank Efficiency

Optimize Aeration Tank Efficiency

What is an Aeration Tank?

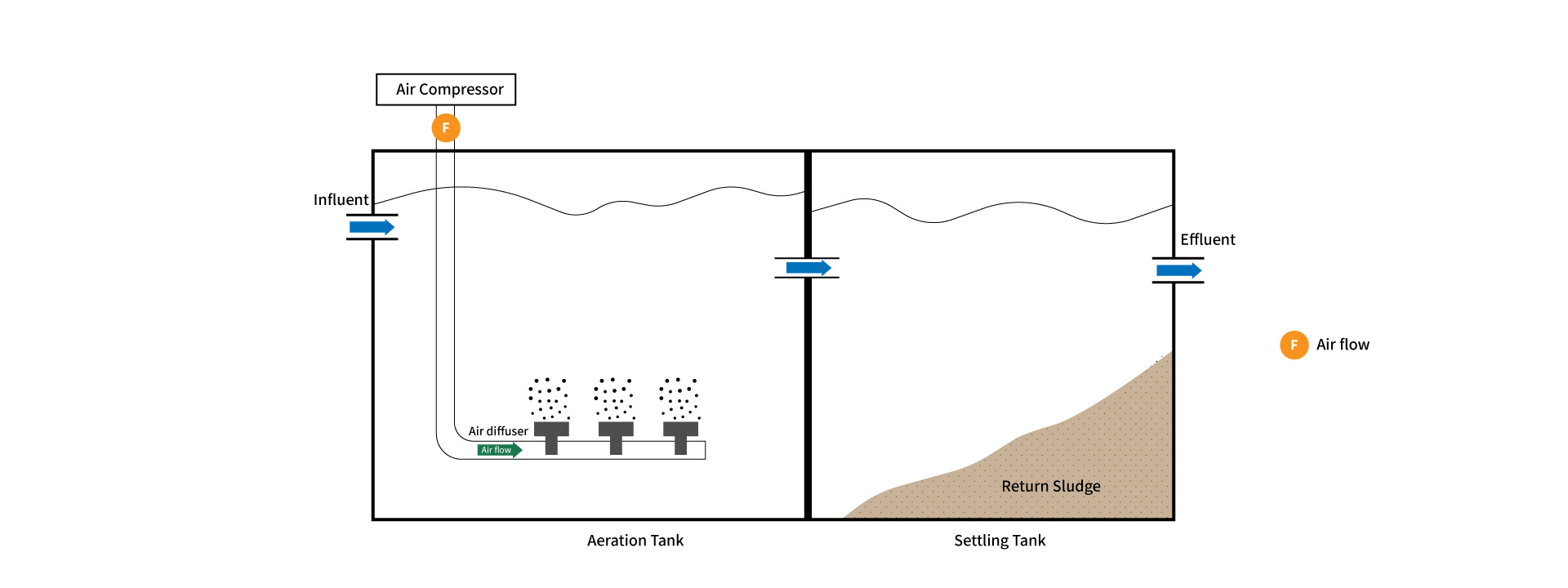

An aeration tank is a key facility in the wastewater treatment process that introduces compressed air into the sewage to supply oxygen, promoting the breakdown of organic substances in the wastewater by microorganisms to achieve purification. When compressed air is introduced into the water, it generates numerous bubbles. These bubbles not only carry oxygen into the water but also stimulate circulation within the water, increasing the range of oxygen diffusion, further enhancing the activity and metabolic efficiency of the microorganisms. The aeration tank is a core component of the activated sludge process, and its operational efficiency directly impacts the overall performance of the wastewater treatment system.

Importance of the Aeration Tank

The primary function of the aeration tank is to effectively degrade organic matter and remove nutrients like nitrogen and phosphorus from the water, preventing eutrophication. The continuous supply of compressed air provides oxygen while bubble formation promotes water circulation, ensuring that oxygen is evenly distributed to meet the metabolic needs of microorganisms. However, supplying compressed air requires significant energy; therefore, precise control of the air supply can not only save energy but also improve treatment effectiveness and reduce operational costs. An appropriate level of dissolved oxygen is crucial for maintaining high efficiency in the aeration tank. Excessive oxygen levels can significantly increase compressed air energy consumption, leading to unnecessary energy waste and higher operational costs.

Why Are Transmitters Needed?

Transmitters play a crucial role in aeration tanks by providing real-time data on dissolved oxygen, air velocity, and airflow, enabling operators to accurately adjust the compressed air supply. This ensures that oxygen and water flow are distributed evenly while avoiding unnecessary energy waste. With the increasing cost of compressed air, transmitters help reduce excessive air input, further lowering energy consumption, extending equipment lifespan, and enhancing the economic efficiency and stability of the wastewater treatment system.

Application of Transmitters in Aeration Tank

1. Average Flow Measuring Tube with Differential Pressure Transmitter

The Average Flow Measuring Tube features a multi-port design that provides uniform airflow measurement within the aeration tank pipeline, avoiding data deviation caused by single-point measurements, and ensuring that airflow distribution meets actual needs. Combined with a differential pressure transmitter, it provides real-time feedback on airflow changes, allowing adjustments in aeration to reduce energy waste and prevent the impact of over-aeration on the biological system. When used with a display controller featuring relay functionality, it enables more precise airflow monitoring and automated control, making the aeration system operation more intelligent.

2. Air Flow and Air Velocity Transmitters

The oxygen supply in the aeration tank is handled by compressors, and air flow and air velocity transmitters are used to monitor the amount of air injected into the tank. These transmitters ensure a stable and sufficient oxygen supply to maintain the metabolic efficiency of microorganisms while avoiding energy waste from over-supplying oxygen.

3. Level Transmitters

Level transmitters monitor the inflow and outflow of water in the aeration tank, ensuring that the water level remains within the optimal range to maintain the stability of water treatment. This helps to improve aeration efficiency and prevents overloading the treatment system.

The application of these transmitters allows for precise monitoring of the aeration tank's operating parameters, helping wastewater treatment plants achieve intelligent management, significantly improving treatment efficiency, reducing energy consumption, and ensuring compliance with environmental standards.

AFMP Average Flow Measuring Tube (Pitot tube)

Features : Multi-point averaging. Suitable for large pipes. Resistant to high temperature and corrosion.

Operating pressure : Standard type : Max. 10 bar / High-temp. type : Max. 4 bar

Operating temperature : Standard type : Max. 200°C / High-temp. type : Max. 600°C

Length : 12"(300 mm)

PHM330 Differential Pressure Transmitter

Features : Suitable for industrial application. High pressure resistance.

Measuring element : Hot-wire type diff. pressure sensor, flow-through

Measuring range : ±50 ... ±1500 pa

Output : 4 ... 20 mA / 0 ... 10 V / RS-485

Accuracy : ±1.5% F.S. ±3% M.V.

IP rating : IP65

DPM04 Flow Totalizer

Features : 2" LCD display for air/liquid flow transmitters with RS-485 and relay output, for both instantaneous and cumulative flow monitoring

Display readout : Instantaneous flow : 5-digit / Cumulative flow : 8-digit

Input : Current / Voltage / Frequency / Pulse

Output : Current / Voltage / Relay / RS-485

Accuracy : ±0.1% F.S. ±1 digit

IP rating : IP65 (Front panel)

FTM94/95 Industrial High Accuracy Thermal Mass Flow Transmitter

Features : Designed for industrial application. Air flow measurement up to 120 m/s. Resistant to high temperature, high pressure, dust, and corrosion.

Sensor type : Pt20 / Pt300(Air velocity) / Pt1000(Temp.)

Measuring range : 0 ... 120 Nm/s

Output : 4 ... 20 mA / 0 ... 10 V / RS-485 / Impulse

Accuracy : ±1.5% F.S.

IP rating : IP67(Probe) / IP65(Housing)

FDM06S Differential Pressure Type Air Flow Transmitter

Features : Adopting the differential pressure principle for air flow measurement enables bi-directional airflow measurement and Calculates medium density and mass flow rate.

Sensor type : Differential pressure sensor

Measuring range : Standard version : ± (0.8, ..., 40 m/s) / High-pressure version : ± (10, ..., 200 m/s)

Output : 4 ... 20 mA + RS-485 / 0 ... 10 V + RS-485 / Frequency (0 ... 100 Hz) + RS-485 / Pulse (Option) + RS-485

Accuracy : ±1.5% F.S. (Option±1% F.S.)

IP rating : IP65 (Body) / IP20 (Probe head)

The use of these transmitters makes the aeration tank operation more intelligent and automated, greatly enhancing treatment efficiency, reducing energy consumption, and ensuring that water quality meets environmental standards.