Smart Monitoring for Compressed Air Systems: eyc-tech Transmitter Solutions

Smart Monitoring for Compressed Air Systems: eyc-tech Transmitter Solutions

CONTENTS:

☛ 1. Introduction

☛ 2. Compressed Dried Air System (CDA)

☛ 3. Applications of Transmitter in Compressed Air Systems

☛ 4. eyc-tech Transmitters for Compressed Air Systems

☛ 5. Integration of HMI (Human-Machine Interface)

☛ 6. Conclusion

1. Introduction |

In industrial applications, compressed air systems play a critical role, but their energy consumption is substantial. To align with the global trend of governments promoting energy conservation and sustainable development, various energy-saving and efficiency-enhancing technologies have been applied to compressed air systems to reduce energy waste.

These include energy-saving inverters, intelligent control systems, and air velocity and airflow transmitters. By precisely monitoring data and achieving effective carbon footprint management, businesses can not only avoid excessive energy consumption and reduce operating costs but also achieve their energy-saving and carbon-reduction goals. This document will explore the integration of compressed air systems with airflow transmitters and dew point transmitters, providing efficient solutions.

2. Compressed Dried Air System (CDA) |

What is a Compressed Dried Air (CDA)?

A Compressed Dried Air primarily compresses air to a higher pressure while removing moisture generated during the compression process to provide clean, dry air required for industrial applications. These systems are widely used in industries such as manufacturing, food and beverage, medical equipment, and chemicals, ensuring that the compressed air meets specific quality standards. The system works by first drawing in atmospheric air, compressing it, and then performing dehumidification and dust filtration. The processed air achieves the desired cleanliness and dryness, ready for use in various processes.Equipment in the System

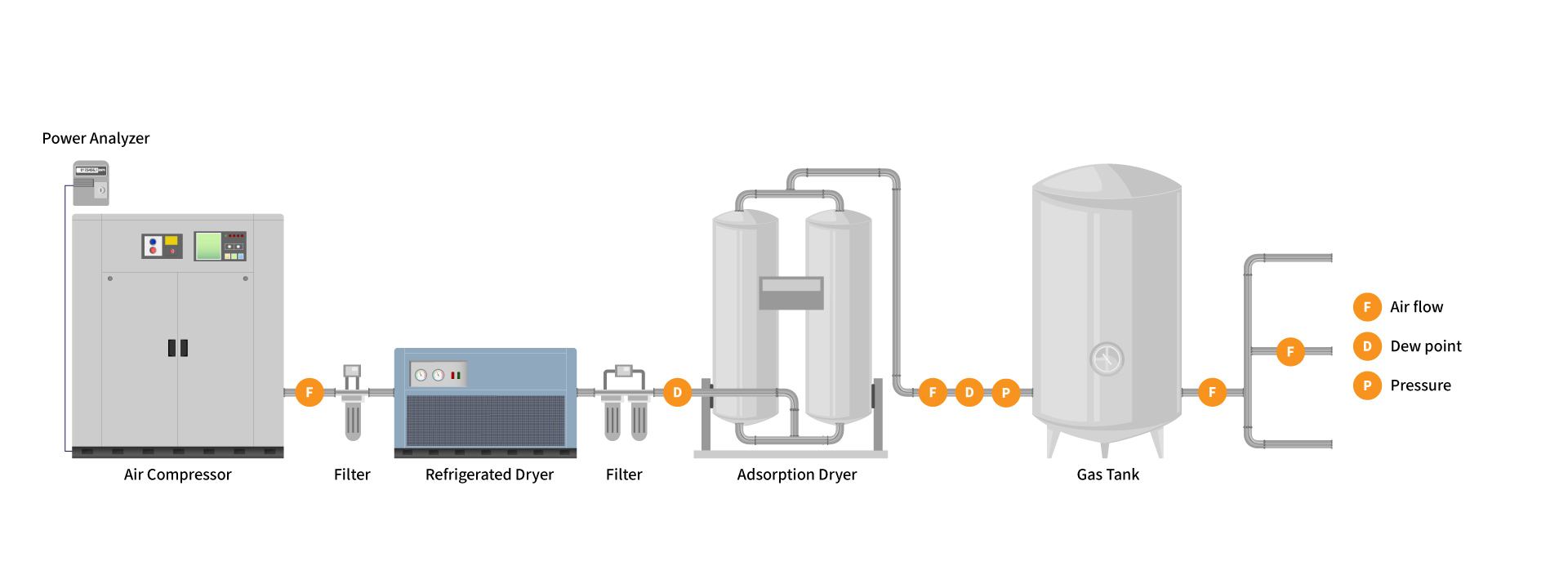

Compressed dried air systems play a crucial role in modern industry by providing not only the power and control air needed for operations but also ensuring the air's dryness and cleanliness to meet high-precision process requirements. The effective operation of this system relies on the coordination of several key components and the precise monitoring of critical parameters by transmitters. The main equipment and their functions are as follows:

-

Air Compressor

The air compressor is the core of the compressed dried air system, responsible for compressing atmospheric air to the required pressure, providing a stable air source for the entire system. The performance and stability of the compressor directly impact the system's efficiency.

-

Air Receiver

The air receiver stores compressed air, acting as a buffer to ensure stable air supply even with varying demands. It helps balance system pressure fluctuations and provides continuous, stable compressed air.

-

Filter

The filter's role is to remove solid particles, oil mist, and other contaminants from the compressed air, ensuring its cleanliness and preparing it for the drying process. -

Dryer

The dryer removes moisture from the compressed air to ensure its dryness. Common types of dryers include:

▶ Refrigerated Dryer: Uses cooling technology to condense moisture from the compressed air into liquid, which is then expelled from the system, suitable for general drying needs.

▶ Desiccant Dryer: Utilizes adsorbents to absorb moisture from the air, ideal for applications requiring extremely low dew points, such as electronics manufacturing and medical equipment. -

TransmittersTransmitters play an indispensable role in the system by monitoring pressure, air velocity and airflow, temperature, and dew point parameters. They ensure the system operates efficiently and reliably. Through real-time monitoring and data feedback, transmitters help prevent equipment damage, optimize energy use, and maintain air quality to industrial standards.

Applications of Compressed Dried Air

Compressed dried air is essential in various industrial fields, especially where high purity and low moisture content are crucial. It is widely used in the electronics manufacturing industry to clean and dry precision electronic components, preventing moisture-induced short circuits or corrosion. In the food and beverage industry, compressed dried air is used in packaging, filling, and bottling processes to avoid moisture contamination and maintain product hygiene. In the medical field, it is used in respiratory devices, anesthesia equipment, and other pneumatic medical devices to inhibit microbial growth and ensure patient safety. The chemical industry also relies on compressed dried air for material transport and instrumentation control, especially in moisture-sensitive reaction processes to prevent instability. Additionally, in the plastic drying process, dry compressed air effectively removes moisture from plastic pellets, preventing defects in finished products.Enhancing the Efficiency of Compressed Dried Air Systems

Improving the efficiency of compressed dried air systems is crucial not only for stable operation but also for achieving energy savings and carbon reduction goals. By precisely controlling and monitoring various system parameters, energy consumption can be effectively reduced, equipment lifespan extended, and high-quality dry compressed air supplied. This not only lowers operational costs but also significantly reduces carbon emissions, contributing to environmental protection.

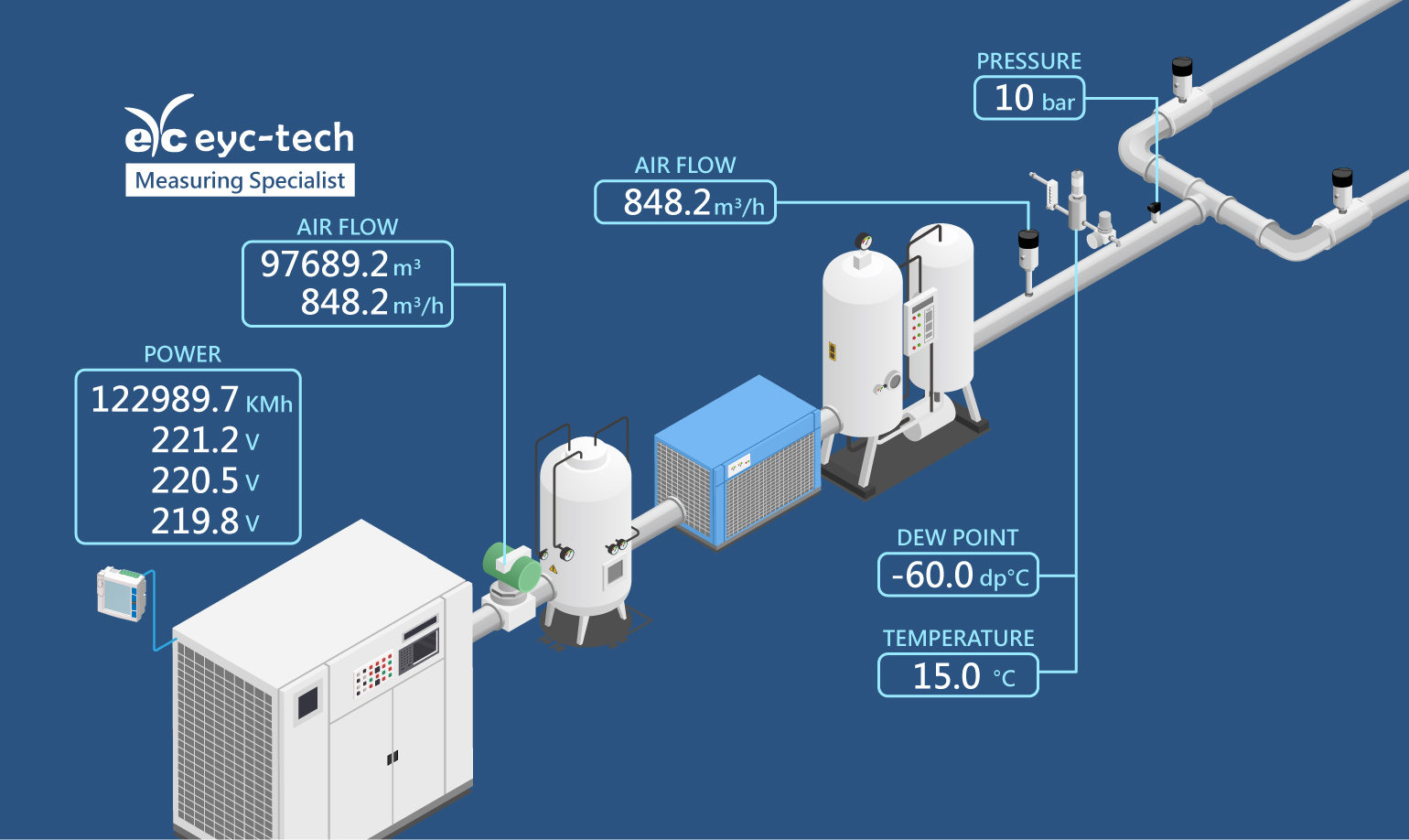

To achieve these goals, the application of various transmitters becomes essential. These transmitters can monitor critical indicators such as flow, dew point, pressure, and temperature in real-time, providing precise data for operators to adjust operating parameters promptly, ensuring the system runs at optimal conditions. At the same time, by improving energy efficiency and reducing wasteful consumption, transmitters play a crucial role in driving energy savings and carbon reduction efforts.

3. Applications of Transmitter in Compressed Air Systems

Transmitter technology has extensive applications in compressed air systems, including:

-

Monitoring Air Supply and Flow

Precise monitoring of air supply and air flow is closely related to ensuring that the system provides a stable air flow that meets process requirements. By using high-precision flow transmitters and pressure transmitters, the system can automatically adjust the air supply to accommodate different production stages, preventing issues such as insufficient or excessive air supply. Additionally, these transmitters help monitor overall exhaust volume, optimizing system operating parameters, improving production efficiency, and reducing operating costs.

-

Detecting Air Dew Point

Dew point transmitters are essential components in dryers, specifically designed to measure the dew point temperature of compressed air. The dew point temperature is the temperature at which moisture in the air begins to condense, which is crucial for ensuring the air’s dryness. In high-precision applications such as electronics manufacturing and medical equipment, air dryness directly impacts product quality and safety. Therefore, dew point transmitters must offer high precision and long-term stability to ensure the system provides air that meets standards, preventing moisture-related issues in processes and equipment.

-

Leak Detection

Leak detection is a critical energy-saving measure in compressed air systems. By using pressure transmitters and airflow transmitters, the system can monitor abnormal changes in pressure and flow, allowing for the timely detection of leaks. Leaks not only lead to energy waste and increased operating costs but may also affect overall system efficiency. By quickly detecting and repairing leaks, businesses can significantly reduce energy consumption, extend equipment lifespan, and improve system reliability. -

Optimizing Energy Efficiency

Compressed air systems are often among the largest energy consumers in a factory, making energy efficiency optimization crucial. By precisely monitoring pressure, flow, and dew point parameters, transmitters can dynamically adjust the operation of compressors and dryers to achieve optimal energy use. Additionally, power monitoring instruments are vital tools for optimizing energy management, providing real-time monitoring of equipment power consumption, identifying high-energy-consumption areas, and making adjustments. This not only helps reduce operational costs but also minimizes environmental impact, contributing to sustainable production goals. Optimizing energy efficiency also extends equipment lifespan and reduces maintenance needs. -

Monitoring System PressurePressure transmitters play a critical role in compressed dried air systems, especially in key equipment such as compressors and air receivers. By continuously monitoring pressure levels within the system, pressure transmitters can detect abnormal conditions, such as excessively high or low pressure, which may lead to system instability or equipment damage. Stable pressure control helps maintain overall system efficiency, extend equipment lifespan, and reduce maintenance costs.

4. eyc-tech Transmitters for Compressed Air Systems |

Wet Air Velocity and Air Flow Transmitters

Dry Air Velocity and Air Flow Transmitters

A dryer in the air compressor system removes moisture from the compressed air to produce dry air for use. Dry air applications are suited for hot-wire flow measurement principles, so the fast-response FTM06D Thermal Mass Flow Transmitter and FTM06D-I Inline Type Air Flow Transmitter can be used. The FTM06D offers a high measurement range of up to 120 Nm/s, providing effective flow monitoring, reducing improper air use, and ensuring optimal equipment performance.

>> Click to Watch - Explore the eyc-tech FTM06D Insertion Flow Meter

>> Click to Watch - Explore the eyc-tech FTM06D-I Inline Flow Meter

Small-Diameter Air Velocity and Air Flow Transmitters

To maintain the stable operation of pneumatic equipment, it is essential to monitor air flow in smaller diameter pipes. For this purpose, the FTE120-I Inline Type Air Flow Transmitter or the FDM06-I Venturi Thermal Mass Flow Meter can be used. The FTE120-I transmitter offers various diameter options, compact size, and easy installation, making it suitable for limited spaces. The FDM06-I, with advanced hot-wire differential pressure technology, provides precise air flow measurement with low pressure drop, rapid response, and high sensitivity, delivering stable measurement results across a wide flow range, particularly for air flow monitoring at the end-use points of compressed air systems

Features: Multiple pipe diameter options for post-compressor system applications.

Sensor type : Thermal mass flow sensor

Measuring range : 0 ... 1500 l/min

Output : 4 ... 20 mA / 0 ... 10 V / RS-485 / Frequency / Pulse

Pipe size: DN10 / DN15 / DN20 / DN25

Accuracy : ±2% F.S.

IP rating : IP 65 (Housing) / IP20 (Probe)

Dew Point Transmitters

In compressed air systems, moisture can cause equipment damage or affect product quality, making it essential to install a dew point transmitter at the dryer outlet to measure air humidity. The THS88MAX Industrial Dew Point Transmitter and the THM88MAX Industrial dew point transmitter with display are suitable choices. These transmitters offer fast response times, excellent interference resistance, and temperature compensation features, providing reliable and long-term stable dew point monitoring. They are effective for monitoring the performance of adsorption dryers.

Advantages of Product Integration: In adsorption dryers within compressed air systems, dew point measurement is often performed using sampling methods. This involves using an air sampling system to collect dry air and send it to the dew point transmitter for analysis to determine the current dryness of the air. For installation, dew point transmitters that allow for easier subsequent removal are preferred. Additionally, controlling the flow rate entering the sampling chamber, typically between 1-3 l/min, is beneficial for precise measurements.

Pressure Transmitters

The Huba 511 pressure transmitter is primarily used in critical points within compressed air systems, including the compressor outlet, storage tanks, piping systems, filters, and dryers. These transmitters provide real-time pressure monitoring, ensuring that the compressor operates within its optimal range, preventing abnormal pressure in storage tanks, detecting leaks or blockages in pipelines, and assessing the performance of filters and dryers. Additionally, the real-time data provided by pressure transmitters aids in system safety monitoring and fault prediction, helping to avoid equipment failures and accidents. By offering precise pressure measurements, pressure transmitters effectively enhance system efficiency and safety.

Power Analyzer

The CARLO Power analyzer for three-phase systems plays a crucial role in compressed air systems. It measures and records the system's power consumption in real-time, including parameters such as voltage, current, power factor, and power. This helps in precisely understanding the energy usage of compressors and related equipment, analyzing load balance, assessing system performance, and managing costs. Through long-term recording and real-time monitoring, the CARLO three-phase power analyzer also assists in fault diagnosis, optimizing energy use, improving operational efficiency, and controlling costs.

Medium : Liquids and gases

Pressure range : -1 ... 0 – 60 bar

Output : 0 ... 5 V, 1 ... 6 V, 0 ... 10 V, 4 ... 20 mA, ratiom. 10 ... 90%

Accuracy : typ. < 0.3% fs

Electrical connection : Swift connector, metri pack, M12x1, connector DIN 175301-803-A or C, braids, connector RAST 2.5

Pressure connection : Inside thread or outside thread

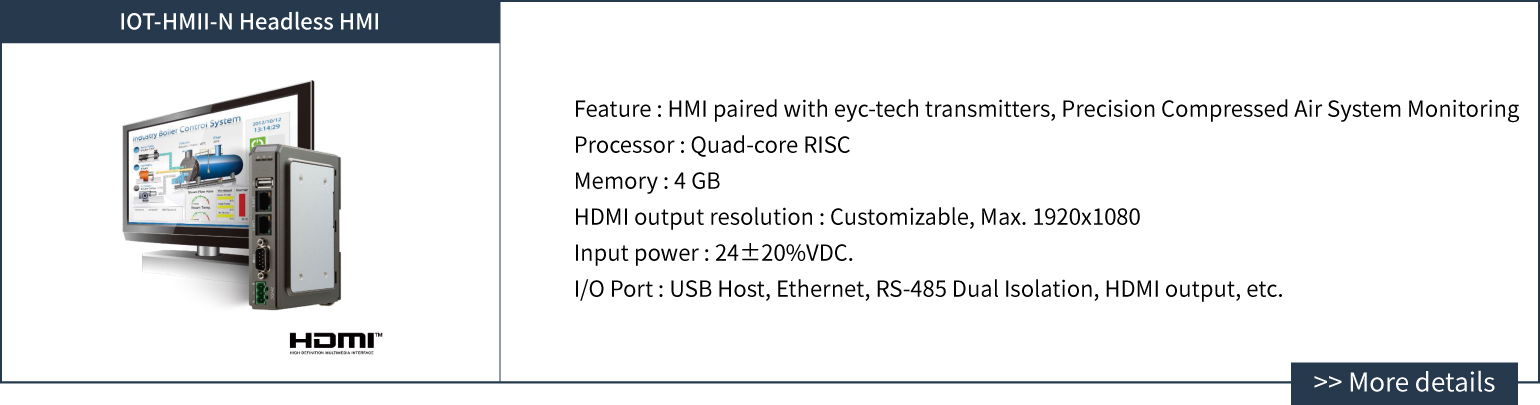

5. Integration of HMI (Human-Machine Interface) |

As the global trend towards net-zero carbon emissions continues, industries are actively seeking more intelligent measurement solutions to enhance energy efficiency and comply with emission regulations. Taking compressed air systems as an example, widely used across various industries, their primary function is to supply clean air to various industrial equipment or tools in manufacturing, pharmaceuticals, food, chemicals, and automation. eyc-tech transmitters, when combined with HMI (Human-Machine Interface), facilitate data integration, centralized management, and precise measurement, enabling real-time monitoring of energy usage and assisting customers in achieving more efficient and intelligent parameter monitoring.

Real-Time Monitoring and Response

Transmitter can instantly detect changes in various environmental conditions or device statuses, while HMI presents this data to operators in an intuitive manner, achieving real-time monitoring and prompt response.Fault Detection and Warning

In the event of abnormal data from transmitters, HMI can promptly display such information, assisting operators in taking immediate measures to prevent faults or carry out rapid maintenance.Enhanced Operational Efficiency

HMI provides an intuitive operating interface, allowing operators to quickly grasp the system's operational status. The data from transmitters contributes to the precise control of automated systems, thereby improving overall operational efficiency.Data Analysis and Optimization

HMI can graphically present the data collected by transmitters, facilitating data analysis for operators to understand system performance, enabling optimization and improvements.Remote Monitoring and Control

Through remote HMI systems, operators can monitor and control distant devices or systems, making remote management more convenient and enhancing the flexibility of remote operations.

6. Conclusion |

The performance and efficiency of compressed air systems largely depend on the application of various transmitter technologies and the integration of HMI systems. Through advanced air velocity, dew point, and pressure transmitters combined with intelligent HMI systems, precise control and management of compressed air systems can be achieved, whether it's for wet air, dry air, or small pipe diameters. This enhances system reliability and operational efficiency, providing more stable support for industrial production.